PROJECT CASE STUDY - Whitemead Forest Park - Royal Forest of Dean, Gloucestershire

Project Case Study - Whitemead Forest Park - Royal Forest of Dean, Gloucestershire

“Working with Target was a seamless experience from start to finish. They took our ideas and made them a reality, guiding us through every step of the process. The new café has not only met but exceeded our expectations, and we’re excited to see how our guests respond this summer.”

Whitemead Forest Park, an independent holiday park destination nestled in the picturesque Royal Forest of Dean, has experienced significant growth since the COVID-19 pandemic, thanks in part to the rising popularity of staycation holidays. To meet the evolving needs of guests and enhance its facilities, Whitemead recently partnered with Target Catering Equipment with a view to upgrade various aspects of the park’s amenities. This collaboration began with a kitchen overhaul and has since expanded to a new quick serve kitchen café development, aiming to deliver an enhanced experience for guests and create an additional revenue stream for the business.

STAGE 1: UPGRADING THE EXISTING

The relationship between Whitemead and Target started with the goal of modernising the park’s main kitchen. The initial project involved eliminating gas from the kitchen and upgrading to a fully electric cookline. This shift not only improved kitchen efficiency and speed but also resulted in reduced energy costs.

Building on this success, Whitemead further collaborated with Target to revamp the wash-up area, equipping it with a high-capacity Meiko pass-through double basket dishwashing machine and bespoke Target dishwash tabling system with the capacity to handle the park’s busy operations. These upgrades significantly enhanced the kitchen’s functionality, enabling staff to meet peak demand with ease.

BEFORE…

AFTER…

STAGE 2: EXPANDING THE VISION - A NEW DOG-FRIENDLY CAFÉ CONCEPT

Following the success of the kitchen renovation, Whitemead once again partnered with Target to undertake a new and ambitious project: converting an unused outbuilding into a dog-friendly café.

This initiative aimed to cater to guests with pets who were unable to access the indoor dining facilities, while simultaneously adding a new revenue stream for the holiday park.

The goal was to create a seamless extension of the park’s indoor ambiance into the new outdoor café.

PROJECT PLANNING AND DESIGN

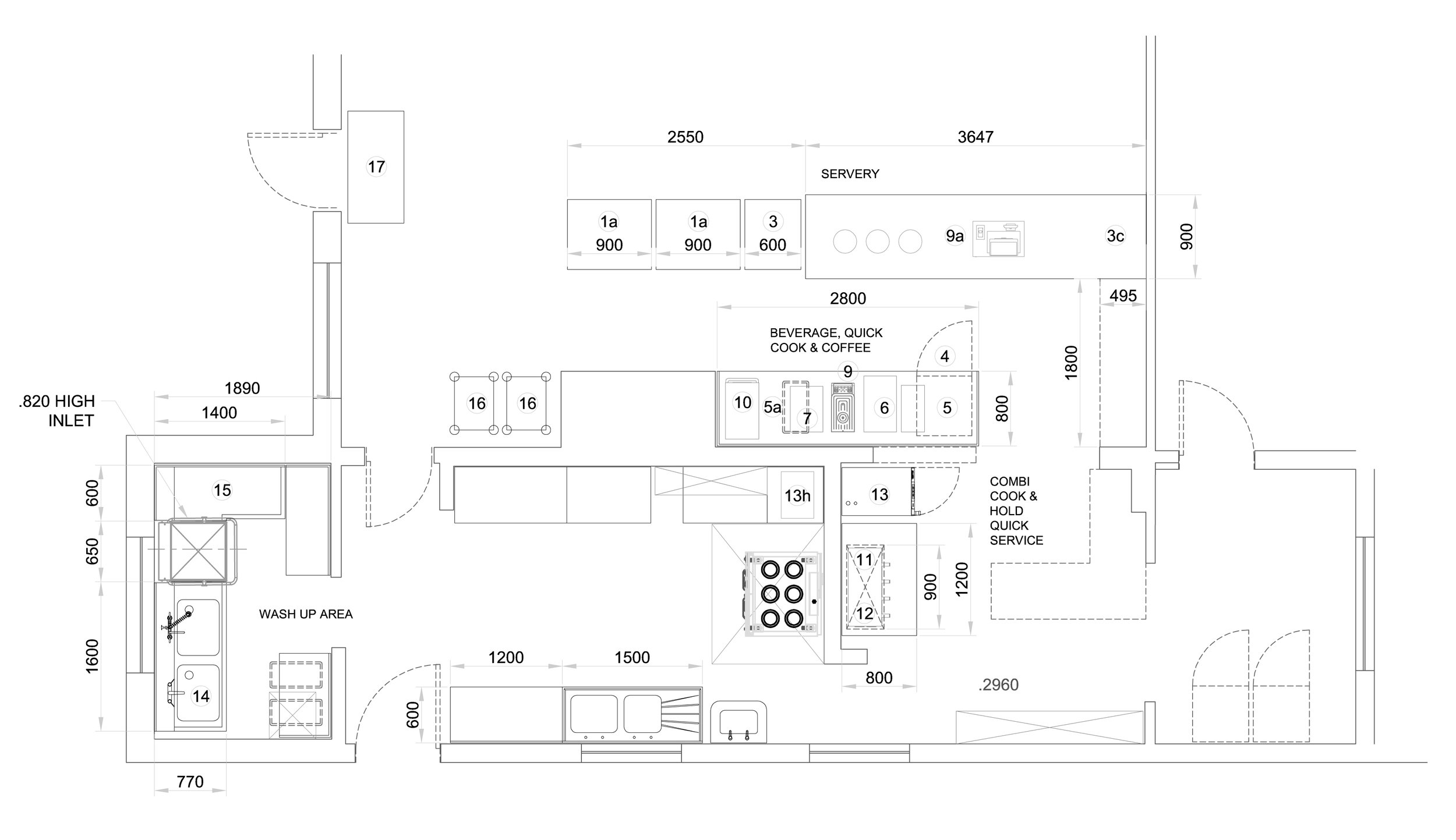

Target’s involvement began with an initial site visit to assess the outbuilding and understand Whitemead’s vision. With a clear understanding of the requirements, Target developed a comprehensive design proposal.

The initial layout was adjusted to optimize the use of the limited space, with considerations for seating, kitchen equipment, and overall flow.

The final design emphasized a focus on reheated goods, grab-and-go options, and coffee and cakes, while leveraging the main kitchen for food preparation.

CUSTOMISED SOLUTIONS AND QUALITY CRAFTSMANSHIP

To maintain consistency with the park’s existing interior design, Target crafted a bespoke café counter that reflected Whitemead’s desired aesthetic. The counter featured a specially selected stone top, sourced from local supplier Tudor Granite, ensuring a unique and high-quality finish. The café was also equipped with high-performance equipment, including a carefully chosen high-speed oven that was tested and demonstrated to meet the needs of the new operation. Following these trials, an additional unit was installed in the main kitchen to further enhance service capabilities.

For the wash-up facility, the café was fitted with the latest undercounter dishwasher from Classeq, simplifying both user and maintenance. Target also provided custom back-of-house fabrications, including handwashing stations, open and enclosed storage solutions, ensuring the café’s operations ran smoothly.

“We’ve had the pleasure of working with Whitemead Forest Park, a renowned local Gloucestershire business, to support them through various stages of their business development.

After proving the success of their original holiday park concept, Whitemead made a brilliant decision to reinvest in their future by building on their already thriving foundation.

At our core, we specialise in delivering tailored solutions, and we’re delighted to have helped bring their vision to life. From the revitalisation of the main kitchen at the ‘Foresters Bar’, to the creation of the dog-friendly ‘Wild Boar Café’, it’s been exciting to see these ideas come to fruition.”

From Concept to Completion

Throughout the project, Target’s team worked closely with Whitemead from the design phase through to manufacture and installation, ensuring the café was completed on time and within budget. The project concluded ahead of the park’s summer 2025 opening, providing Whitemead with a fully operational café that aligned with their original vision.

Conclusion

The Whitemead café project showcases how a well-coordinated partnership can transform underutilized spaces into valuable assets. Through innovative design, customized solutions, and close collaboration, Target successfully delivered a dog-friendly café that complements Whitemead’s offerings, enhancing guest experience while driving additional revenue for the holiday park.

PROJECT CASE STUDY: Cotswold Halt - Toddington, Gloucestershire

The owners of Cotswold Halt, a coffee shop that primarily serves visitors to the Great Western Steam Railway in the Cotswolds, approached Target for help transforming their struggling, outdated establishment. Once a truck-stop style venue, the goal was to create a warm, inviting space that could cater to both regular customers and special events, such as steam train enthusiasts and tourists attending the railway’s themed events.

Target collaborated closely with the railway committee to create a clear vision for the space. After in-depth consultations, Target developed a tailored proposal that balanced modern commercial kitchen technology with the specific needs of the coffee shop’s diverse clientele.

BEFORE REFURBISHMENT…

Key Solutions:

Bespoke Front-of-House Design:

The design for the front-of-house space centered around a welcoming and efficient service area that could handle both everyday customer needs and high traffic events.

This included:

Custom-Designed Service Counter: A tailored serve-over counter featuring hot and cold display units from Cossiga, ideal for showcasing baked goods, sandwiches, and beverages.

Beverage Equipment: High-performance equipment from Lincat and Bravilor to ensure consistent quality and speedy delivery, essential for serving hot drinks during peak times.

Ambient and Refrigerated Storage: To support the diverse range of offerings and maintain efficiency and quality during service.

Back-of-House - Quick Serve Kitchen Concept:

The Quick Serve Kitchen Concept was the perfect fit for the back-of-house area, providing a simple to use, compact, efficient, and versatile solution.

Key equipment included:

Convotherm Mini Combi Oven: A space-saving oven with built-in ventilation hood, offering maximum cooking capacity within a minimal footprint. This allowed for versatile food preparation, from pastries to hot meals.

Duke Hot Holding Units: Flexible tray options allowed for maintaining the consistency and quality of various dishes, crucial during busy service periods.

High-Speed Ovens: These advanced ovens ensured fast heating, enabling quick service during events like the Santa Express and Cheltenham Race Week, where demand peaks sharply.

DURING THE TRANSFORMATION…

Wash-Up Area Transformation:

An often-overlooked part of a kitchen, the wash-up area was a particular challenge in this project due to the limited space available. Target’s in-house design and manufacturing team designed a custom solution that transformed a previously unused room into a highly efficient wash-up area. A Welbilt passthrough dishwasher was installed to ensure fast, thorough cleaning, supporting the cafe’s high turnover during peak events.

BEFORE…

AFTER…

Implementation and Training

Once all equipment was installed, comprehensive training was provided by Brand Managers and Development Chefs to ensure the team could fully utilise the advanced technology. Each piece of equipment was configured to align with the cafes specific menu and service requirements. The training sessions ensured that all staff were proficient with the new systems, resulting in smoother, more efficient operations.

Today, Cotswold Halt, is thriving, with its modern kitchen setup and revamped service areas supporting a high volume of customers during major events such as the Santas Express and Cheltenham Race Week. The transformation has not only improved the cafe’s daily operations but also elevated its ability to serve the railway’s special events, ensuring a welcoming atmosphere and efficient service.

Conclusion

Target’s expertise in kitchen design, equipment selection, and custom manufacturing enabled Cotswold Halt to successfully transition from an outdated coffee shop to a modern, event-ready venue. The combination of advanced technology, personalised service, and hands-on training resulted in a kitchen that meets the demands of both daily customers and large event crowds, contributing to the cafe’s revitalised success.

Farm Ed - Evenlode Valley, Oxfordshire

Farm Ed, an amazing philanthropic project with a mission to accelerate the transition towards regenerative farming and sustainable food systems by providing space and opportunity for inspirational education, innovative research, practitioner led knowledge exchange events and personal development.

Based on a working farm in the rolling Oxfordshire Cotswold area, a stone’s throw away from a GWR main line railway station at Shipton under Wychwood and Matthews Cotswold flour mill, Farm Ed is home to two brand new impressive eco-buildings - one built to provide a space for conferences, lectures, workshops and special events; and the other a farm to fork kitchen and food space, and a regenerative business incubator.

In 2019, with the structural build under way, Owner Ian Wilkinson approached local catering equipment firm Target Catering Equipment to assist with the design, supply and install of a suitable commercial kitchen facility that would meet the needs and beliefs required for this project.

PROJECT BRIEF

Ian tasked Target to design a modern kitchen facility on a budget, to be used for Farm Ed’s aptly named Farm Eat facility. The very compact back of house kitchen space was to be multi-functional so that it could be a space for start-up businesses to test out their concepts, whilst also operating as a kitchen to service the function rooms as well as the food hall that was soon to be home to a traditional Italian wood fired oven, the main focal piece installed specifically for the use of cooking fresh produce and keeping the facility warm.

THE PROCESS

Target’s design team set to work designing a commercial kitchen concept that would incorporate a combination of new and used catering equipment. A sustainable option for the start-up concept that was also fitting of the project’s ethos, giving pre-owned products a second life. As the structural build neared completion, the small kitchen design evolved, it was decided that for the cookline there was a preference for a gas open burner oven range that was simple to use and common to most chefs, particularly those new to the industry just starting out that would be transferring from a domestic style kitchen to a commercial operation. This was to be complimented by the UK’s very first “ventless” Hoodini CombiSlim combination oven, complete with its android based operating system that could be used for so many different styles of cooking including roasting, baking, steaming, and grilling etc.

For more information on Ventless Catering Equipment - Click Here

The choice of a ventless combination oven meant ventilation costs could be kept down as it allowed for a standard Lincat SmartVent canopy that would be gas safe interlocked with air quality monitoring built-in to safeguard staff from potential harmful by-products of combustion from the gas fired equipment in the kitchen and solid fuel wood fired oven used in the food hall.

The small basic cookline with a larger than expected potential capacity would be serviced by the flexible prep area consisting of bespoke manufactured prep sink that easily transformed into a work bench through the use of sustainable bamboo chopping boards. Gram refrigeration prep counters and upright fridge and freezer with touchless foot operated opening doors, designed and specified to reduce touch points in the kitchen, along with Lincat hot cupboard to hold food warm for service with heated gantry over to maintain piping hot food.

And finally, the dishwashing system made up of bespoke dishwash tabling and Meiko Upster passthrough dishwasher with Mechline GreasePak and BioCeptor drain maintenance system to address FOGs produced within the kitchen. This was also complimented by Mechline Basix hands-free hand wash station featuring knee operated taps, so once again reducing touch points for infection control within the kitchen facility.

THE END RESULT

Following a quick and easy installation with Farm Ed’s local contractors providing all plumbing, mechanical and electrical services for Target’s installers to connect to, the kitchen was complete and ready to use. Farm Ed received on-site training of the new equipment and are now up and running with a catering facility dedicated to the production of quality sustainable food.

Farm Ed and Farm Eat offer wonderful facilities with an environmentally sustainable ethos that is unique and will promote all that is good in agro-ecology - what better legacy for the future could one provide. Hats off to all the team at Farm Ed and Farm Eat for what they are doing and achieving to make a real difference.

The Talbot - Knightwick, Worcestershire

The Talbot at Knightwick is a Grade II listed traditional coaching inn which has been a well-known gathering point within the local community since the 15th century. Independently owned and managed by the Clift family for over 30 years, The Talbot is an award winning quintessential British pub with rooms located on the picturesque banks of the River Teme, with an ethos of keeping things simple and being authentic and excellent in everything they do.

In 2019 the pub was devastated by flooding due to being situated on the natural flood plain of the River Teme and as a result a complete refurbishment of the property including a new bar and commercial kitchen was required to get the business up and running again.

Due to the position of the pub and the inevitability that the river would burst its banks and flood the property again, insurers NFU decided to put a criterion in place that required the business to put together a plan of action to minimise future potential flood damage to the building and the property within. It was at this time when The Clift’s Surveyor engaged Target Catering Equipment as professional consultants for help and advice on carrying out the project.

PROJECT BRIEF

The aim was to design a flood resilient bar and commercial kitchen to replace the existing ones. The pub kitchen however did not house typical commercial kitchen equipment but had evolved over many years from using wood and coal solid fuel cooking stoves, to a Farmhouse style kitchen incorporating multi-oven oil fired AGA and LPG gas fired equipment.

The kitchen equipment and layout would need to facilitate a traditional British hearty pub food menu, which focused on using only the freshest ingredients from suppliers in the local community and produce gathered from their very own kitchen garden and allotment.

With the previous running costs of oil and LPG gas fired equipment within the kitchen at a high and a three-phase electrical power supply available at the property, Target suggested this would also be an ideal opportunity to consider ways in which the pub could improve its energy efficiency and minimise ongoing running costs.

Owner and Chef Annie was initially reluctant to replace the much-loved inefficient AGA which she favoured for her unique cooking techniques and recipes that made the Talbot what it was to date, however agreed and decided, based on Target’s recommendations that it would be best to proceed with an all-electric commercial kitchen design incorporating the very latest commercial induction cooking technology.

THE PROCESS

Target’s commercial kitchen design team worked together with the owner/chef, surveyor and management and prepared a design for a completely mobile and modular commercial kitchen which could easily be disconnected and moved safely out of reach of the flood water via enlarged kitchen access doors, prior to a known flood risk situation, meeting the criteria of the insurers and the client’s operational needs.

The kitchen was situated across two levels within one section of the property which subsequently made up the upper kitchen area and lower kitchen area. The lower kitchen was designed with two prep areas favoured by Steve Thorley, Annie’s right hand man and operations manager, with dedicated prep sinks and Gram refrigerated counters, Robotcoupe prep machines and a floor standing planetary mixer. A starters/desserts section complete with Houno CombiSlim 10 grid combination oven, bespoke Target solid top induction stove, Lincat Opus 800 fryer and hot cupboard with heated gantry. A main cookline with another Houno CombiSlim 10 grid combination oven, bespoke Target solid top induction suite, Lincat Opus 800 fryers and chip scuttle and service pass with Lincat hot cupboard with heated gantry, two stacked microwaves and Gram refrigerated counter with gantry over.

As the cooklines were designed to be made up using all electric catering equipment, there would be no harmful by-products of combustion, as with gas cooking equipment, which would normally need to be removed using an expensive gas interlocked balanced exhaust and tempered mechanical supply air ventilation system. Instead, two Britania kitchen ventilation canopies exhausting at low level through an external wall could be used, keeping kitchen ventilation system costs to a minimum, not to mention being simple and easy to keep clean.

In the upper kitchen area was a new pot wash area, consisting of dirties drop off and clearing station with double bowl dish wash inlet tabling complete with spray arm and lever arm taps, a Meiko Gio pass through dishwasher, outlet tabling and four tier stainless steel drying/storage racking. In order to minimise the risk of blocked drain issues the dishwash system was to be fitted with a drain maintenance system including a GreasePak bio enzyme dosing module and BioCeptor FOG interceptor and treatment unit. Mechline Basix handsfree handwashing facilities were also located around the kitchen and at the entrance/exit points of the kitchen in accordance with Covid-19 health and safety operational guidelines to ensure sufficient handwashing facilities would be available to anyone entering the kitchen space.

The front of house bar area incorporated Lincat IMC Bartender modular bar units and bespoke stainless-steel fabrication from Target along with a Hoshizaki ice machine and Classeq glass washer for a dedicated glass washing facility. By using modular bar units again in the event of a flood these could be uplifted and moved to safety to ensure minimal damage.

Once the layout designs and equipment specification had been approved, all the necessary mechanical and electrical service drawings were prepared and provided to suit the proposed kitchen and bar layouts. Contractors could then set to work installing all new services. The point was made to make sure all electrical connection points were made at high level well above the historic and most recent flood levels, noted as the highest so far. All electrics were installed to the very latest IET regulations providing personal protection from electric shock.

With the existing walls and floors suffering from flood damage, Target recommended new wall and flooring finishes that would be resistant to future flooding. Following the difficult task of preparing the building’s sub floors, new Altro resin coved floors and Altro white rock hygienic panels were installed, making for an easy to clean sterile kitchen environment that would minimise the potential for water damage in the future.

Once the kitchen shell was complete with the mechanical and electrical services installed, it was just a case of installing the equipment which could be easily rolled into position and plugged in ready to go.

THE END RESULT

Owner and chef Annie was nervous about using the new technology, however soon warmed to it following on-site training provided by equipment manufacturer’s development chefs for each individual pieces of cooking equipment. The fear of cooking using induction was soon overcome when it was used to cook her mother’s much loved porridge recipe just as she had done for years under her mother’s discerning eye on her old faithful AGA that the Target solid top induction replaced.

The handover was completed and despite facing so many obstacles, the Talbot was once again after such devastation, ready, willing, and able to return to the new normal hospitality industry following the lifting of the 2nd Covid-19 lockdown on the 2nd of December 2020.

The Pizza Planet - Cam, Dursley

The Pizza Planet - pizza, burger and wrap takeaway shop originally opened in Cam, Gloucesterhsire in 1998. Following year on year profits generated by the succesful quick service takeaway restaurant, owner Mr Yavari was able to re-invest in his business and as a result set up three further ‘The Pizza Planet’ franchise takeaway restaurants. In 2019, the unit next door to the Cam restaurant which was previously operating as a beauty salon became available, Mr Yavari jumped at the opportunity of acquiring the property with the view to expanding his flagship site.

After 21 years in business, the entire takeaway shop and kitchen in Cam was well overdue a refurbishment. This meant that the expansion into the next door unit had come at just the right time as now both the refurbishment and expansion could be combined. Mr Yavari’s main aim for the expansion and refurbishment, was not to increase throughput and profit, but to improve the working environment for his staff, many of whom had proved themselves to be loyal and hardworking employees having worked at The Pizza Planet for many years.

PROJECT BRIEF

The existing quick service restaurant was extremely tired and worn, overall the layout of the takeaway kitchen was compact and struggled to house all the equipment, ingredients and consumables required to keep up with demand and as a result made it difficult for staff to operate safely and efficiently.

Walls, floors and ceilings needed replacing, as maintaining a high level of cleanliness on damaged surfaces proved an almost impossible task for kitchen staff.

The heavily used gas fired kitchen appliances including conveyor pizza oven, griddle and fryers in the small kitchen space generated excessive amounts of surplus heat. Combined with a dated extraction system not operating effectively, with minimal fresh air supply, made for an insufferably hot kitchen especially in summer months.

With an idea in mind, Mr Yavari decided to contact Target for assistance on the project. Having worked together with Target’s MD David Pedrette many years prior when Mr Yavari was setting up his first ever UK based takeway business, he was confident that David and the team at Target could deliver the quality end result that he was looking for.

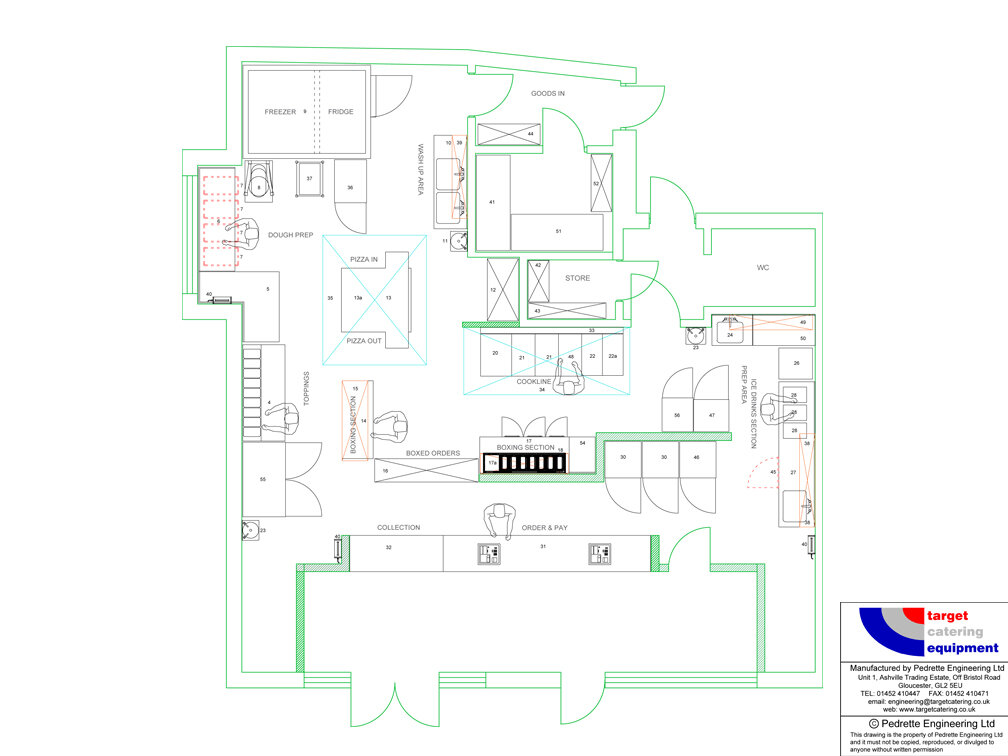

After an initial consultation to discuss his requirements for the business, and a full site survey, Target’s designers David and Nicola set to work to prepare a suitable commercial kitchen layout and ventilation system design for the soon to be expanding flagship site.

Key factors to be considered in the design were;

Improved Working Environment

Workflow & Efficiency

Health & Safety: Hygiene, Cross-Contamination etc.

Re-use of “Good” Existing Equipment

Increase Storage Space

THE PROCESS

The kitchen layout was designed specifically to allow for maximum space and a clear flow from start to finish for each cooking process; pizza production, grill and fried product production and beverage production which in turn would minimise crossover of staff from each area including back of house kitchen staff and front of house service and delivery staff. This also meant the front of house order, delivery and collection systems could run more smoothly without interuptions.

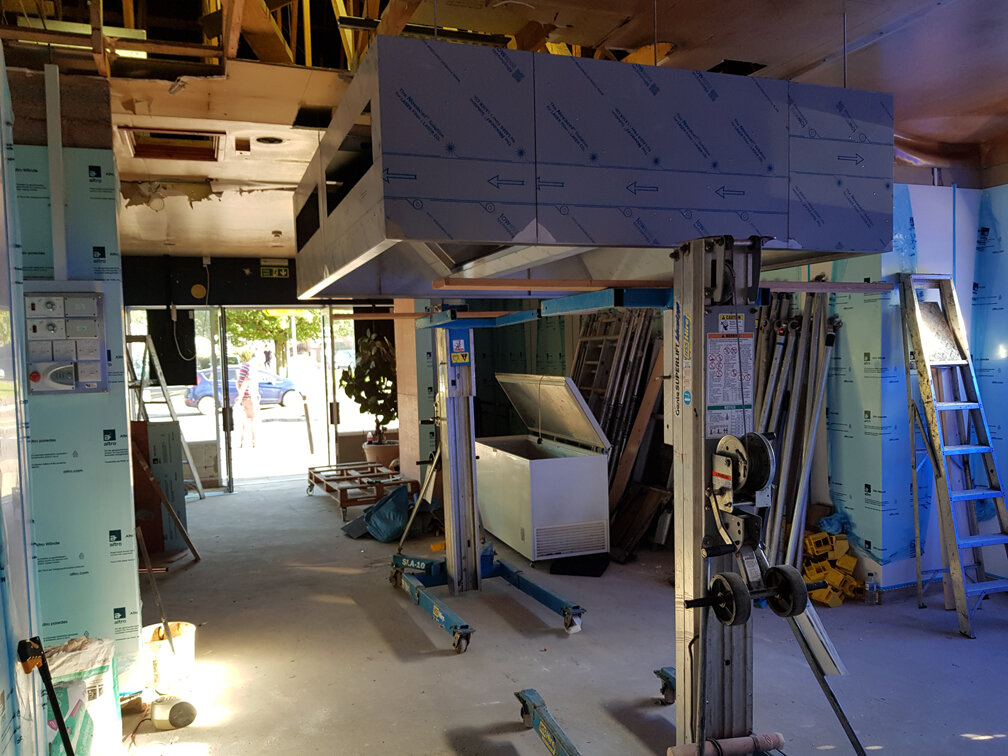

Once the kitchen layout design prepared by Target had been agreed and signed off, the transformation process could begin. The project involved knocking through two units to create one larger space. Mr Yavari’s team set about stripping out the exisitng store units in order for contractors to carry out building works, m&e electrical and plumbing upgrades and fitting of new Altro hygienic surface fininshes to walls floors and suspended ceiling. Everything including the existing extraction system was taken out to be replaced, with some equipment being serviced and re-used in the new commercial kitchen scheme.

With a tight schedule to meet, whilst building works on site were getting underway, Target set to work manufacturing bespoke stainless steel items ready for installation of equipment in the following weeks.

The new equipment to be installed included; Hoshizaki Gram refrigeration prep counters, Middleby UK conveyor pizza oven, Blue Seal griddle, fryers and chip scuttle, Target prep and packaging benches, sinks, gantries and service counter, and Fosters walk-in refrigeration.

THE END RESULT

“Working with Target completely transformed the business” said Yavari. “Having worked with other suppliers previously, it was a pleasure working with one of the best again having enjoyed a relationship with David Pedrette MD of Target since the opening my first joint venture shop in Gloucester back in the 1980’s when I arrived in the UK following the revolution in Iran and David was an installer for a local catering equipment manufacturer in Gloucester.”

When the business reopened in September 2019 following the complete refurbishment and rebrand, who would have known the Covid-19 pandemic was lurking around the corner in 2020. The Covid-19 pandemic has proved to be catastropic for many food busineses but following a year of trading during these difficult times, Mr Yavari states he has seen at least a 20% increase in business as a result of being able to continue trading as the business was so simply and easily able to conform with the Government guidelines of sanitation, separation and flow within his shop, with in and out customer doors and simple service counter screens, along with all the regular sanitation measures put in place.

To discuss your refurbishment project with Target Click Here.

The Bell Inn - Selsley, Stroud

16th Century grade two listed Cotswold inn, The Bell Inn, located in the quaint village of Selsley, is a fine example of a typical traditional Cotswold pub with rooms. Serving up real ales, locally sourced food and seasonal game on a daily basis.

COMMERCIAL KITCHEN DESIGN & PLANNING

In April 2017 Chef Proprietor Mark Payne decided that it was time to upgrade the existing small kitchen by building an extension and converting all gas appliances to electric. Mark approached Target Catering Equipment, as local Carbon Trust Accredited Suppliers, to work with him on the project to design and deliver a sustainable kitchen that could meet all his needs.

The kitchen cookline was designed to encorporate the very latest Target TR-E+ Range complete with induction hobs and induction plancha, Unox 5 grid combination oven and Lincat electric fryer. The huge potential energy savings that could be made when compared to the existing gas appliances was apparent and therefore warranted a Carbon Trust Green Business Funding application to be made.

Following an Energy Saving Assessment completed by Target and the review of the application by the Carbon Trust, the Bell Inn Green Busniess Funding application was successful and they were granted £4,129.50 which would help offset the expenditure for the energy efficient equipment.

INSTALLATION

Whilst the kitchen renovation was being completed Mark wanted the pub to remain fully operational so a temporary kitchen was hired for 2 weeks while the major building work took place. The kitchen doubled in size by removing a central wall and a new backwards facing kitchen extraction canopy was manufactured and installed by Target.

The ventilation canopy incorporated smaller twin fans to help reduce noise in the kitchen, this also provided a natural stack ventilation system. Consequently the fans now do not need to be operational all the time, helping to provide a quieter working environment for the kitchen brigade.

By repositioning and converting the cold room and freezers, large cold rooms were formed and the pastry section completely changed to become a dishwashing area with Classeq pass through dishwasher. Existing sinks and tabling were joined together to create a more streamlined operation whilst keeping costs down.

The pastry section is now located away from the busy main cookline with its own table and induction hobs. It also benefits from its own Turbofan® covection oven with steam injection.

An island for prep was formed to take sous vide and vac pac machines, microwaves and salad bar with existing counter fridges and fitted with bespoke Target 2 tier gantries complete with power feed from above.

COMPLETE KITCHEN REFURBISHMENT

Following completion of the kitchen renovation the Bell Inn continues to grow from strength to strength and has subsequently been recognised in the 2018 Michelin Guide, 2017 Good Food Guide (Waitrose), been awarded with 2 AA Rosettes for Culinary Excellence and received a 5 star hygiene rating by environmental health and a 4 Star AA quality inspected rating .

Mark and the team at The Bell are excited for the future of their business, and are looking forward to all of the opportunities their investment will bring.

Lexicon Healthcare, Green Tree Court Nursing & Dementia Care Home - exeter

Lexicon Healthcare, operators of Green Tree Court, Exeter, an exceptional 5-star nursing and dementia care home, wanted to be able to offer a 5-star a la carte menu for residents and their guests in any one of the 5 dining rooms or in the residents private rooms.

Unfortunately, they had inherited a kitchen that was dysfunctional. The original commercial kitchen was gas fired, and had a noisy and inefficient ventilation system with ducting that was poorly designed and the fans were inaccessible in the roof space; this made the adjacent rooms unable to be offered for resident's use.

OLD COMMERCIAL KITCHEN

Head chef, and 2017 Masterchef competitor, Tim Ware researched a number of companies to advise and suggest solutions but ultimately selected Target Catering Equipment. The kitchen needed to be redesigned and the existing ventilation system completely re-engineered and replaced.

Tim wanted the new commercial kitchen to be designed to include a new and energy efficient cookline, chefs' pass, new cold room, beverage stills area, pastry section and prep areas so the kitchen could function more efficiently. With a fully waited service to residents' rooms and 5 dining areas the kitchen brigade needed to be able to quickly and efficiently deliver to the pass.

Once the new kitchen design and specification had been signed off, Target Catering Equipment was assigned as main contractor overseeing the 4-week scheduled refurbishment. With the existing kitchen out of use for this period of time, residents were still needing to be catered for, Target facilitated a portable temporary kitchen and storage container to replace the main kitchen whilst the work took place.

OLD KITCHEN EQUIPMENT RIP-OUT

WALLS, FLOORS & VENTILATION INSTALLATION

NEW EQUIPMENT INSTALLATION

Set against a new service wall which effectively formed an island wall cookline, a new Rational SCC 6 grid was stacked on top of the existing combi master and positioned alongside a new bespoke Target induction suite with integrated fryer and Target plancha. The chefs now had a powerful and energy efficient cookline. The addition of the new service wall enabled the creation of a usble perimeter prep and pastry section and also utilised the available natural light from the windows.

Storage space was increased and a new Foster Coldroom with remote compressor and condensers fitted. The new fans mounted on the roof will make the cleaning and maintenance of the ventilation system easier and all ducting has access inspection and cleaning hatches which are demountable for deep cleaning purposes.

COMPLETED COMMERCIAL KITCHEN

The pass now has a hot section with a fast action Rise and Fall salamader grill for finishing and browning and a cold section for cold food. The waiting staff have their own new beverage stills area with under counter glass washer and refrigerated storage.

The whole project was completed on time and on budget to the delight of the owners and the kitchen brigade headed up by Tim. The residents now enjoy freshly prepared a la carte food created in a the kitchen which is now an organised and comfortable environment to work in. Nosiy fans have gone, and the ventilation system requires minimal use. All thanks to the team of designers, engineers and installers organised by Target.

Camberley Heath Golf Club - Camberley, Surrey

Camberley Heath Golf Club welcomes prestigious guests, members and visitors to enjoy their facilities in Camberley, Surrey on a daily basis, whilst also hosting various special events throughout the year.

With a large kitchen facility the golf club offers a variety of food throughout the day, into the late evening along with catering for larger events and private dining.

However, as the kitchen was powered soley by gas fired equipment, this meant each year it would run up huge utility bills due to the in-efficiency of this equipment.

Looking for advice, Head Chef, David Heath contacted Target to discuss possible solutions in becoming a more efficient and sustainable commercial kitchen.

The existing cookline contained three six burner gas ranges, a gas solid top range, a gas salamander grill and two Rational combination ovens. The main concern was the excessive wasted energy generated by the gas ranges and the gas salamander grill.

This resulted in the replacement of the existing gas equipment with two bespoke induction suites which incorporated a French plancha and FriFri filtration fryer alongside heavy duty induction cooktops. Accompanied by a fast action rise and fall salamader grill and Blue Seal Turbofan® convection ovens.

With it's limited ventilation system requirements, the commercial kitchen induction stove setup was ideal for producing the la carte menu and offering an early morning back bar cooking facility whilst complimenting the cooking capacity of combination ovens for events and wedding catering.

INSTALLATION

New Target Bespoke Commercial Induction Stove

Existing Gas Fired Catering Equipment

With the kitchen was being used on a daily basis, it was imperitive that there would be minimal downtime and disruption during installation. With this in mind the Target bespoke induction ranges were the perfect choice for Chef David as they are manufactured completely off-site for quick and easy installation to pre-installed services. The access to the kitchen was up 3 flights of stairs. The units were therefore specially designed as two modular sections rather than a large single unit to enable them to be lifted easily and safely into position.

The Target installation team arrived on site for an early start. The golf club's local gas engineers were on-site to remove the exisitng gas equipment with the Target team following swiftly behind installing the new induction suite, having it all up and running ready for the 9am start for breakfast.

The kitchen now operates efficiently with their new Target bespoke commercial induction range in place, and with happy chefs working in a more comfortable working environment.

For more information on Target bespoke commercial induction ranges CLICK HERE.

Jordans Mill - Biggleswade, Bedfordshire

Located on the banks of the steady-flowing River Ivel stands the historic flour mill, Jordans Mill. Purchased by the Jordans Family back in 1893 at a time when Bedfordshire was home to over 400 flour mills and a major centre of flour production within the region. In 1894 a tragic fire tore through the entire mill which presented the family with the opportunity to carry out a full rebuild, replacing old milstones with the latest milling machinery, turning Jordans Mill into one of the leading most advanced of its time, that is still standing today.

Over the 20th century Jordans Mill continued innovating, becoming part of the worldwide granola movement which started in the 1970's and created the famous Jordans Original Crunchy that fast became one of the nation's favourite breakfast cereals.

Since 1992 when William 'Bill' Jordan (VI) and his brother David Jordan took over the family owned mill, the business has grown and diversified through the introduction of new products and has since opened its doors and gardens, becoming a vistors centre and facility for corporate and private events.

COMMERCIAL KITCHEN DESIGN PROCESS

Opening to the public in April 2013 by HRH Prince Charles, Jordans Mill decided to introduce a basic food offering to the vistors centre which included lite bites, breakfasts, teas, coffees and cakes, along with buffet style hot meals which proved to be a massive success. However due to the variety of visitor types Jordans Mill needed to cater for, the food offering rapidly grew and the set-up became in-efficient and unable to keep up with demand. In 2016 both Bill and David decided it was time to review the catering side of the business.

Wanting to focus the food offering and improve the operational efficiency within the commercial kitchen through investing in the latest innovative commercial catering equipment they began their search for a company that could take control of the entire project from the initial concept design, through complete commercial kitchen design, manufacture, supply and install.

PROJECT BRIEF

The existing food hall offered a buffet/self service style of operation which was causing queues at service and payment points. These bottle-necks would encroach into the dining area, taking up usable cover space, whilst also causing a disruption to the operation of the kitchen, which in turn affected the quality and consistency of food being produced. Because of this, management at Jordans Mill decided they wanted to implement a table serviced restaurant style operation.

The poorly laid out kitchen was making use of an inefficient and slow 6 ring electric radiant plate range and outdated combi-oven, which impacted greatly on consistency and resulted in extremely high utility bills. This, combined with a lack of work space resulted in cross overs between prep and cook areas within the kitchen which became a main concern due to the potential for cross contamination.

Catering Manager Tom wanted to review the choice of current equipment in order to improve the quality and consistency of food as well as being able to cater for large corporate and private events with ease. Not only that, but being an open kitchen, it was improtant that the kitchen would be easy to keep clean and organised, allowing kitchen staff to run a smooth operation.

COMMERCIAL CATERING EQUIPMENT

With efficiency, speed, consistency and volume in mind Target Catering Equipment design consultants were instructed to prepare a complete new kitchen layout and servery design.

During the design process the in-efficient existing equipment began to fail and it became a necessity for the main cooking range to be replaced. With the knowledge that they wanted to switch to induction technology and with the power supply available, management decided to purchase an "Off The Shelf" Standard Target Restaurant Range with fast action rise and fall salamander grill over, which would be available immediately for use, and would keep operations going until the scheduled refurbishment.

The new cookline was then designed to incorporated this unit and was transformed with the addition of a Frima 112T VarioCooking Center, a Lincat/Rational SelfCookingCenter and a Target Bespoke commercial induction range with built in FriFri fryer and refrigerated drawer. All selected and approved following site visits to see the new innovative commercial kitchen equipment technology in use.

All new cookline equipment was to be situated in a new island configuration and completed with a new service manifold, designed to support the new 5.3m extraction canopy. This extraction canopy was only part of the new extraction system which also included new fans and ducting, which had to accommodate very low ceilings and duct outlets pre-formed in the green oak framed visitor centre and reuse existing outlets with no visable external alterations to the building.

Combined with the new cookline was a separated prep area complete with Gram refrigerated counters and Robot Coupe food preperation machines, and a new utensil/potwash area complete with Granuldisk Granule SMART machine.

The bespoke service counter was designed to use natural materials that would replicated the current style of the property whilst also being functional with hot cupboard and heated gantry over.

COMPLETE KITCHEN INSTALLATION

With designs being signed off in September 2016 and a refurbishment shutdown period scheduled for January 2017, this gave the Jordans Mill project management team 3 months to source and schedule local sub-contractors who would be involved with the project.

A complete set of installation drawings including M&E service drawings, bills of quantities and detailed specifications were prepared specifically for the project to be put out to tender to local subcontractors who would work alongside the Target Catering Equipment kitchen installation team in order to keep project labour costs to a minimum.

As scheduled in January 2017 works began which involved rip out of old equipment, counters and services, the installation of new commercial catering equipment, new Altro vinyll floors and PVC wall cladding, a new electrical distribution system, a complete new ventilation system including 5.3m long extraction canopy and service manifold, along with building work necessary to improve the flow of the kitchen.

With the help of the careful planning provided by the project management team, the complete commercial kitchen installation carried out by Target Catering Equipment ran like clockwork and was completed on schedule by the end of January 2017 ready for the new season.

This refurbished facility now showcases the very latest kitchen technology as chosen by Owners David and Bill Jordan, who still remain very hands on when it comes to keeping the mill at the top of the league and a destination of choice for discerning visitors in Bedfordshire.

Box-E (Chef Elliott Lidstone) - Wapping Wharf, Bristol

Throwing caution to the wind, Chef Elliott Lidstone decided that after spending years of his life working his way up through the ranks in the likes of Michelin starred restaurant L'Ortolan where he became head chef, before spending four years at the Empress in East London earning himself two AA rosettes, a Michelin Bib Gourmand and 32nd spot in the top 50 gastro pubs in the country in 2016, it was time to go it alone with his partner Tessa and take a shot at making their lifelong dreams come true!

Bristol's new vibrant harbour-side shipping container development Cargo 1 - Wapping Wharf was soon to become home to their new venture.

TURNING DREAMS INTO REALITY

Elliott and Tessa approached Target Catering Equipment with a vision of turning two shipping containers into an intimate restaurant with complete kitchen that would allow Chef Elliott Lidstone to deliver his specialist dishes.

It was down to Target to prepare a complete kitchen layout design that would include, preparation area, cookline, service line, wash-up area and Chef's table all within just 10m².

Working closely with Elliott to ensure his kitchen was exactly as he wanted whilst being within his budget, the cookline was designed to consist of a Target TR-R restaurant induction range complete with commercial plancha and Adande refrigerated drawer, rise and fall salamander grill, Rational combination oven and fryer. The remaining kitchen layout being made up of refrigerated counters, prep benches, a dishwasher, dishwash tabling and storage.

Layouts approved, the install was ready to proceed.

With the containers being situated on an upper level meant that access was limited, the most efficient way to manoeuvre the equipment was for it to be craned up. Being an all-electric kitchen meant there were minimal regulations to adhere to and no costly gas installation requirements. Equipment was simply wheeled into position connected to pre-installed services and ready for handover.

Finishing touches to the interior completed, the restaurant was ready to open!

Reaping the benefits of their hard labour, Elliott and Tessa are now owner operators of a thriving restaurant nestled alongside an eclectic mix of other independent traders.

Box-E caters for 14 covers and includes 4 seats at the chef's kitchen table which offers a unique dining experience where guests can enjoy a seven-course tasting menu complete with a matching wine flight.

Since opening in October 2016 Box-E has already been announced as number 85 in Britain's top 100 restaurants in the National Restaurant Awards with Elliott Lidstone nominated as a Chef to Watch also by the National Restaurant Awards. Box-E is also being recognised as one to watch and a must visit by The Michelin Guide, BBC Good Food, - Fiona Beckett, The Sunday Times - Ed Cumming, The Guardian - Jay Rayner and Crumbs Magazine - Andy Clarke.

It is clear the new arrival of Box-E on the Bristol food scene is one not to be missed!

Visit boxebristol.com to book a table.

Planning on opening your own restuarant? Find out how we can help turn your dreams into a reality -Speak to a Target designer.

Bonny Inn - Salesbury, Lancashire

PROFESSIONAL INDUCTION STOVE COMPLETES ISLAND INSTALL

Designed and manufactured to be millimetre perfect in order to fit into the kitchen, the Target, energy efficient professional induction stove is the latest addition at The Bonny Inn, chosen by Micheal Heathcote to complete his new central island kitchen design.

The island induction cooker incorporates two mirror finished planchas and slide controlled induction solid top for multiple pan use along with round and square induction coils for stock pot cooking.

Integrated under the induction cooktop is a Blue Seal E31D4 convection oven which fits snuggly alongside Target's remotely mounted induction generators. Positioned for optimum cooling of the induction cooktops the remotely positioned generators allows extra space for useful adjustable storage space under for pots and pans.

An overhead rise and fall salamander grill compliments the cookline and pass having automatic plate detection and hot holding capacity as well as fast action grilling capability.

The professional induction stove has its own built in electrical distribution system which only requires one connection to incoming 3 phase mains power making installation quick and easy for the team of Target engineers.

A combination oven, charcoal oven and grill alongside FriFri fryers and Merrychef accelerated cooking system, compliments the cookline, providing this small but perfectly formed kitchen with a wide range of cooking systems to produce high quality output to cater for every taste at this well renowned hostelry.

For further information about Target's professional induction cooking range pelase call 01452 410447.

The Bridgend Hotel - Bridgend, Isle Of Islay

COMMERCIAL INDUCTION RANGE TRANSFORMS GAS KITCHEN

Head Chef, Scott Chance of the Bridgend Hotel, Isle Of Islay, was tasked with redesigning his kitchen. Scott had his own ideas but needed the help of a kitchen design specialist to turn these into reality.

After contacting Target Catering Equipment, Scott visited the Target factory, showroom and demonstration kitchen, based in Gloucester. This enabled him to take away many ideas and suggestions which would help him decide on his ideal kitchen design.

Following his research, Scott knew he wanted to replace existing gas cooking equipment with induction cooking technology and decided on incorporating a Target professional induction stove into the main cookline.

Having relayed his ideas, the Target design team produced a complete kitchen design along with detailed mechanical and electrical service plans so local building main contractor John McKechnie had a blue print to prepare the kitchen services ready for the Target installation team to install the equipment. The Altro hygienic wall, floor and ceiling systems, which were recommended by Target, were also prepared by John and his team.

The old building housing the kitchen needed windows removing to allow access for Scott's smoke room equipment, including a Bradley smoker, but all the other catering equipment, including the induction cooker, was on castors so could be easily manoeuvred into place.

Gram refrigeration was specified for this reomote island location as it is covered by Gram's 5 year extended manufacturer's warranty and also because it conformed to high eco design standards. The Gram fridges are fitted with heavy duty castors which make them easy to move and therefore ideal for cleaning and maintenance in the busy catering kitchen.

Compatible standard heights for the mobile counter fridges ensured level work surfaces throughout the commercial kitchen. The Gram compact fridges and freezers fitted perfectly under the work surfaces and additional Target gantries were manufactured to fit over the work surfaces increasing usable work space.

A new dishwashing facility was designed by Target to reduce clutter and maximise efficiency. Fabricated with custom made sinks designed with creamer edge clearing racks; these would prevent drips and spills. Fully welded and enclosed upstands reduce dirt traps and make cleaning easier on all Target specialist fabrications.

The commercial induction range, the design of which Scott decided upon following extensive trials and investigation, included flat and ribbed double planchas alongside round induction coils for stock pots and large pans and square induction coils to replicate the old gas solid top which Scott had loved to cook on. These were all incorporated into a continuous work surface alongside an inset Fri Fri double basket fryer with filtration.

A bakery style E27M3 4.7Kw Blue Seal turbofan oven was under mounted in the induction stove. The oven was chosen for its simplicity, reliability and even oven temperatures with twin contra rotating convection fans capable of taking 3 off 600 x 400MM baking trays.

Above the induction cookline a full length plate and grill rack was fitted to provide additional storage space for the kitchen's utensils. A fast action, rise and fall salamander grill was also positioned above th induction cooktop. This grill was the latest hi-touch model, with new program options which allow cooking times and temperatures to be set so dishes are cooked to perfection whilst saving energy and reducing temperatures in the kitchen.

The Bridgend Hotel catering kitchen installation was completed on time and on budget with Target and local contractors working together. The end result was a very happy head chef and hotel manager and a transformed kitchen.

Kingham Plough - Chipping Norton, Oxfordshire

Commercial Kitchen Transformed by Target

Located in the Oxfordshire village of Kingham, near Chipping Norton, the Kingham Plough has achieved a happy balance between a 'proper' pub and an exceptional dining room. Since opening in 2007, Chef Proprietor Emily Watkins and her husband Miles Lampson have followed their ethos that provenance is the key to great food and they continue to source only the best local ingredients, both for the kitchen and bar.

Their succes is reflected in their numerous awards. This year alone the kingham Plough has been awarded their prestigious third AA Rosette, been placed 72nd in the top 100 restaurants in the National Restaurant Awards, have won the Oxfordshire Dining Pub of the Year in the Good Pub Guide for the second year running, and continue to be recommended in the Michelin and AA guides amongst many others.

In addition to the dining pub, they have six comfortable bedrooms upstairs for customers to really make the most out of their Cotswolds experience.

As a family-run pub, the Kingham Plough is both child-friendly and dog-friendly, maintaining a relaxed and welcoming atmosphere that is comfortable, friendly and inclusive. It is everything that an exceptional Cotswolds dining pub with rooms should be.

ABOUT EMILY WATKINS

Executive chef Emily Watkins has put everything into building her business and career as a chef, working tirelessly to produce delicious dishes, developing her own style of modern British cuisine.

Over the years Emily has featured on numerous TV productions including The Hairy Bikers, Tom Kerridge's Proper Pub Food, whilst also regulalry appearing in the local, national and international press.

In 2014 Emily competed in the BBC's Great British Menu, winning with her fish course. Following this Emily was selected to cook her winning dish for war veterans at St Paul's Cathedral in a banquet commemorating the 70th anniversary of the D-Day landings, and has since returned to the show as a veteran judge for the South West Region.

COMMERCIAL KITCHEN DESIGN PROCESS

After the whirlwind of being heavily in the limelite as a prestigious chef, Emily Watkins and husband Miles Lampson decided it was time to invest in their business and improve their dated kitchen by introducing an energy efficient, eco friendly, erganomically designed commercial kitchen.

Emily needed a company to help turn her ideas into reality, having previously worked with Target Catering Equipment, based in Gloucester, she got back in contact and asked Target's design team to work with her to transform her kitchen.

PROJECT BRIEF

The old kitchen at the Kingham Plough was poorly designed, highly unproductive and inefficient, using LPG bottled gas which produced a lot of waste heat that the ventilation system could not cope with, especially during the summer months making the kitchen unbearable at times for staff.

Equipment was being left on for most of the day and not turned off because it was difficult to reignite, resulting in high utility bills. The antiquated equipment was also costing a lot to keep running through engineers's service call outs to replace failed thermocouples and to clear blocked gas jets.

Multiple pots and pans were being used that required regular de-carbonising as did all the equipment, as the excessively high temperatures burned on all debris and spills to the cooking equipment and utensils. This again costing the company money.

Being in a traditional Cotswold building the kitchen suffered with uneven floors and walls, causing surface finishes to deteriorate over time. These were to be made good and compliant with Health and Safety regulations, smooth, impervious and easy to keep clean.

With a three phase electrical supply available Emily made the obvious decision of opting for an all electric kitchen. It was now down to Target to design and specify equipment that would meet her needs, which was to include an energy efficient Target bespoke commercial induction range.

COMMERCIAL CATERING EQUIPMENT

Target's design team and Emily looked at how they could improve work flow and productivity and create a better ambience for their kitchen brigade.

The main cookline being transformed with a Target bespoke induction range able to cope with large stock pots and also small multiple pan cooking with a double plancha. Combined with a 10 grid Lincat combination oven would speed up cooking process times, reduce waste heat and minimise energy costs.

Along with the main cookline range Emily decided thata bespoke island induction cooking suite would be ideal for the pastry section. This would be accessible from both sides of the kitchen and once again improve workflow.

Target's design team also recommended other equipment which was specifically desgined to reduce energy consumption. Fosters Eco range of fridges and blast chillers were specified and Target used their stainless steel fabrication facility to customise the units in order to meet Emily's demanding and site specific requirements.

With a new hot pass, a Target fast action salamander grill, and the Winterhaulter, energy efficient heat recovery dishwashing system, despite some earlier misgivings about all the new technology being introduced into the kitchen, staff were soon enjoying the kitchen's transformation.

COMPLETE KITCHEN INSTALLATION

With the complete commercial kitchen refurbishment scheduled for a 2 week turnaround, involving installation of new catering equipment, new Altro resin floors and PVC wall cladding, a new electrical distribution system, extension to the ventilation canopy along with building work to accomodate new storage areas and cold room, the Target team had their work cut out. However, with careful planning and attention to detail the refurbishment was completed 3 days ahead of scheduled handover, allowing Emily and her team plenty of time to prepare for the official re-opening just before the busy Cheltenham race week.

The hard work and planning from Emily and the Target team continues to pay dividends, as the Kingham Plough has recently been awarded 2 stars by the Sustainable Restaurant Association, the kitchen is running more efficiently, energy costs are down and staff morale is up!

WHAT EMILY WATKINS HAS TO SAY ABOUT TARGET

"I chose Target because they were able to totally work with me from beginning to end, from the initial chat stages through the whole design process, creating exactly what we needed."

Emily Watkins - Chef Proprietor of Kingham Plough

The Moat House (The Lewis Partnership) - Acton Trussell, Staffordshire

ELECTRIC INDUCTION HOBS TRANSFORM TRADITIONAL GAS RANGE

With gas solid tops cracking up, open gas burners failing and uncontrollable gas ovens, Group Executive Chef, Matt Davis of the Lewis Partnership's flagship hotel, The Moat House at Acton Trussell, needed help renovating his outdated traditional gas range.

As owner, Chris Lewis, had recently installed energy monitoring equipment throughout the hotel, it was abundantly clear that the kitchen was haemorrhaging energy. With a ventilation system that was struggling to keep up with the production of waste heat from the range and the continuing repair bills just to keep the old gas range going, it was time for a change.

Having looked at many different solutions, Davis discovered Target Catering Equipment and working together, a plan was devised to convert the gas range to electric induction. By installing Target commercial induction hobs, a commercial plancha griddle, pasta boiler and electric convection ovens the gas range would be converted into a commercial induction suite which in turn would transform the kitchen.

On initial investigation it became clear that the chassis of the original range was in good condition although the gas components were not up to the job. With this in mind Target designed a range of drop in electric units and started the job of removing the original built in gas units. And so the transformation began!

Induction hobs replaced the gas burners and the gas ovens were converted to electric convection ovens. The gas fryer was removed and a pasta boiler installed. An overhead high efficiency salamander fast action rise and fall grill was also added.

As all work had to be completed without shutting the kitchen at this busy hotel, the Target engineers worked through the night in order to complete the task of converting the range from gas to an all electric induction range.

Without losing a single day's revenue from kitchen closure, the transformation from gas to electric induction was completed.

Group Executive Chef Matt was delighted with the renovation and his kitchen brigade are now using the very latest induction cooking technology which has transformed the kitchen.

Owner, Chris Lewis, continues to monitor the energy bills and is currently looking forward to a busy and energy efficient hotel whilst his catering staff are looking forward to cooking on induction in a cooler, quicker and more productive kitchen.

Cinderhill Farm - St Briavels, Lydney

Production Kitchen Design Helps Cinderhill Farm's Pie House Double Output

After a year of acclaimed success supplying Cinderhill Farm ‘Foggy’ pasties, pies and sausage rolls, to the M5 Gloucester Northbound motorway services, and with the iminent opening of the new M5 Gloucester Southbound motorway services approaching, the strain on their exisiting production kitchen was becoming apparent. As a result, Cinderhill Farm Owners Deborah and Neil Flint decided a new production kitchen was needed to enable them to double production at Cinderhill Farm's Pie House.

Deborah and Neil contacted local catering equipment company Target Catering Equipment in order to help them come up with a production kitchen design that would allow them to cope with increasing demand and utilise the exisiting footprint at their Pie House based on their working farm in the Forest of Dean, Gloucestershire.

With the project came an added pressure in that production had to continue whilst the refurbishment was to be carried out. Luckily Target was able to assist with this, as a temporary production kitchen was able to be set up in Target’s fully operational demonstration kitchen, perfectly located just off the M5, junction 12.

Target’s commercial kitchen designers worked together with Deborah and Neil to prepare a suitable production kitchen design that would meet their current and future needs.

With the existing ovens unable to cope with increased demand, Target suggested a Rational SelfCooking Center combination oven to increase output, improve consistency and reduce cleaning time. The old gas range cooking facility was replaced with a VarioCooking Center 211 and commercial induction hob cookline. With all equipment featuring HACCP software to record and control the cooking process thus ensuring consistent perfect results every time.

Potwashing and utensil washing by hand and domestic dishwasher was replaced with a energy efficient Granuldisk bead blasting utensil washer. Saving on space, minimising water consumption, removing the need for cleaning chemicals and speeding up cleaning processes.

New refrigerated prep counters and large chopping boards were introduced to speed up preparation and hand forming of the products. Blast chilling before packaging and distribution and storage was improved with a "roll-in-roll-out" trolley system which allowed chilling to be processed direct from the oven. This reduced handling, utensil and baking tray use.

All new Altro Xpresslay adhesive-free vinyl floors and White Rock hygienic finished walls were installed along with a completely new electrical distribution system upgraded to a 3 Phase supply and emergency generator supplies to provide back-up power ensuring production would not be interupted in the event of mains power shortages.

Target designed and project managed the complete fit-out working alongside local tradesmen and builders preparing groundworks and new drainage systems ready for the new kitchen equipment installation.

"The whole project went really well and was made so much easier with the availability and use of the Target demo kitchen" said Deborah. “Whilst utilising the temporary production facility at Target, pie production increased and The Pie House team were able to meet demands of both the north-bound and south-bound Gloucester motorway services. The new kitchen offers so much more space for us to expand, so a fantastic result all round.”

Oak Cantina - Tetbury

Custom Stainless Steel Fabrication Completes Airstream Catering Trailer Fit Out

Having completed the full refurbishment at the Royal Oak Tetbury, owners Chris York and Kate Lewis set their hearts on their next project, a festival style street food mobile catering trailer to be name Oak Cantina, to be homed in the gardens at the Royal Oak, Tetbury, with the added flexibility of a mobile catering outlet to cater at events and festivals, delivering freshly cooked Mexican and Tex-Mex food.

As custom stainless steel fabrication specialists, designing and building commercial kitchens suitable for small spaces is a regular occurrence. It was therefore right up Target Catering Equipment's street when they were commissioned by Chris and Kate to design, build and install a catering facility within an American Airstream 1962 Trade Wind trailer.

With specialist vehicles and trailer conversions needing a road worthiness certificate to allow them to travel on roads in the UK, from October 2014, it was essential that the first task for this project was to get the iconic Airstream IVA tested. Having refurbished and modified the trailer to comply with European and British specifications, the Airstream was then examined at the Avonmouth DVA test station where the modifications passed with flying colours.

Next came the fit out, incorporating custom-built stainless steel catering equipment and a complete mechanical and electrical installation. LPG modular kitchen equipment from the Lincat Silverlink 600 series was chosen by Target for the cookline and was installed on a customised stainless steel framework, allowing the modular cookline to be easily changed if needed to suit varying menu styles.

The front servery counter was again custom-built and fitted onto a roll in-roll out system, incorporating Lincat Seal hot and cold tabletop servery display units, fitted over a bespoke Target hot cupboard and an Adande fridge freezer drawer unit. This enabled the servery counter to slide out under the motorised gull wing side doors and awning. Not only did this provide more working space but also made cleaning much easier within the trailer.

At the front end of the trailer a full-size double bowl catering sink with separate handwash basin and under counter commercial dishwasher system were squeezed in place with a plate draining shelf positioned over. With hot and cold water, along with power connections being supplied to the trailer from external services.

A purpose-built kitchen ventilation canopy and high-level ventilation system was designed, and custom built by Target to ensure a comfortable working environment for the chefs working in the cantina with air quality and safety proven with a gas safety interlock system.

Set in the backend of the trailer is a Kamado Joe, a Japanese style charcoal oven, which is ideal for smoking and slow roasting as well as BBQ grilling and searing. This style of cooking uses lump wood charcoal which gives food a unique smoked flavour.

Target Catering Equipment Managing Director and Project Manager/Lead Designer of Project Oak Cantina, David Pedrette commented, “Installing a kitchen inside an Airstream was never going to be easy. We needed to incorporate bespoke fabrication and use equipment powered by LPG bottled gas, and Lincat’s Silverlink 600 range was the perfect modular solution to combine with our bespoke fabrication. It uses 0.5inch gas supply, which uses minimal fuel, making it cost-effective. Being 600mm deep, it can also be squeezed in neatly under a smaller kitchen ventilation system.”

David continues, “We wanted high quality, multi-discipline kit that could be used to cook a variety of street food. The modular Silverlink 600 range was ideal, and should Chris and Kate want to cater for other cuisines, it can be easily changed for other models in the range. We also chose to include both heated and refrigerated Lincat Seal display units. Food can be displayed well and kept in optimum condition, encouraging purchases. Aesthetically, the equipment had to compliment the look of the trailer, whilst bringing something to the customer experience. Lincat equipment looks fantastic, suits the space and is competitively priced.”

Having been lifted into position by specialist crane operators, the Airstream now enjoys it’s pitch site at the stunning Royal Oak in Tetbury, Gloucestershire, providing a venue for outdoor special events and functions in the large beer garden and entertainment area.

Following a successful launch, Oak Cantina Head Chef, Richard Simms commented, “We served over 300 people on the launch day and are delighted with the layout and all the equipment in the Airstream. The four-burner range is excellent for all the pan work - the hob allows for multiple cooking and it has a very large and well-heated oven, especially considering the small space it had to fit into.”

Gilpin Hotel & Lake House (1 Michelin Star) - Windemere, Lake District

COMMERCIAL RANGE COOKER COMPLETES KITCHEN REFURB

Gordon Cartwright, Executive Chef Director at the Gilpin Hotel & Lake House, decided to switch to an all electric kitchen, commissioning a Target commercial range cooker with induction cooktop and plancha grill for the Michelin starred restaurant.

Visionary Dining founder Cartwright pushed all the boundaries and defied convention with his new kitchen design. The creative kitchen has no defined pass but multiple food preparation and assembly areas, each with its own suspended heat lamp, hot holding section.

Portable induction hobs, sous vide water baths and other table top catering equipment is spread around the kitchen with the Target commercial induction range stove at the centre of the sections all orchestrated by Cartwright.

The induction range cooker requires no overhead ventilation in its central island position, with general kitchen ventilation provided by the original wall mounted extract system, the only thing remaining unchanged from the original kitchen and saving a fortune in refurbishment costs.

Energy efficiency is a key driver for Cartwright and along with the induction stove, Target's fast action rise and fall salamander grill and automatic plate detection bar, energy consumption is greatly reduced allowing an increase in bottom line profitability.

For further information about Target commercial induction please call 01452 410447.

Caffe Vergnano 1882 - Southbank, London

TARGET INDUCTION COOKING RANGE SPECIFIED FOR ITALIAN KITCHEN DESIGN

A Target induction cooking range completes the classic Italian Cafe's cookline for leading London equipment distributor and kitchen designer, Chiller Box Ltd.

Chiller Box re-designed the kitchen at Caffe Vergnano 1882, located in London's Southbank Centre development, and, whilst retaining certain elements to keep the costs down, also supplied new equipment including the bespoke induction cooking range.

The deck pizza oven, Valentine fryers and pasta boiler line up was completed with a Target bespoke induction range which incorporated an induction cooktop and plancha with convection oven and grill under. The bespoke induction cooking range is proving popular as a replacement to the traditional 6 burner gas range and equivalent radiant plate electric range.

Chiller Box designers now specify induction as part of their energy efficient kitchen design package and working together with manufacturer's Target Catering Equipment they can deliver bespoke induction cooking solutions to suit their clients' needs.

Chefs love the instant heat and control that cooking on a Target induction range gives and when used alongside the plancha grill the ideal versatile cooking station is created. With integrated work surfaces and upstands to sides and rear of the induction range, cleaning is made easy as spillages are contained on the worktop, cooking directly on the commercial plancha means less pots and pans and thus reduces time spent washing up.

Induction cooking is the cool alternative!

For further information please call 01452 410447.

Kaskelot - Tall Ship Marine Galley Kitchen

TARGET MARINE GALLEY EQUIPMENT COMPLETES LUXURY TALL SHIP RENOVATION

Tall ship Kaskelot recently left Gloucester Docks following a complete refit and renovation. Together with new marine galley equipment, new main propulsion engine and power generators, new mechanical and electrical control and navigation systems, and newly painted hull, she looks magnificent and has been transformed to a new gleaming vessel.

Hidden in the staff accommodation is a new all stainless steel marine galley. Designed, manufactured and installed by Target Catering Equipment of Gloucester. The marine galley includes a bespoke marine induction cooking suite which incorporates the very latest Target commercial induction cooking technology and replaces old, inefficient LPG gas cookers.

The new commercial induction range produces little or no waste heat which makes the galley a much cooler and safer place to work in. It also provides reduced running costs and reduced fuel consumption which are very important on a vessel of this type.

The galley has everything you would expect to find in a commercial kitchen including; sinks, hobs, oven, microwave, extraction system, refrigeration and storage and through innovative design, this has all been squeezed into a small space with no straight lines or level surfaces, as you would expect to find on a shaped and streamlined ship. With the design approved, the bespoke shaped and height adjustable equipment was accurately templated and manufactured, by Target’s skilled engineers, to suit the curved decks and fine lines of the ship.

Target worked with yacht designers and project managers to ensure a commercial galley kitchen was produced on time and on budget ready for the ship to sail. Her new owners Sportcel are a sports and events marketing company and tall ship Kaskelot will now enjoy her new role in corporate hospitality and marketing around the world.

The ship is a great working exhibit of the fine traditional craftsmanship undertaken by ship builders Tommi Nielsen and Co, based in Gloucester Docks. The refit also used the skills and products from many other local manufacturing businesses.

Target Catering Equipment’s Managing Director, David Pedrette comments; “It’s not often a tall ship comes in for a total refit but that’s just what Kaskelot did, using the skilled shipwrights of Tommi Nielsen’s shipyard and dry dock, one of the few remaining. And, with my marine engineering background, what an honour it was when they approached Target to design and fit out the galley on board. Gone with the old dangerous LPG gas ranges and in with all new energy efficient electric induction ranges suitable for life at sea. It was a challenge but an absolute designer’s dream to fit out this tiny galley space from top to bottom and I think we did this beautiful vessel justice making everything here in the often-forgotten Port of Gloucester.”

Kingsholm Stadium (Gloucester Rugby) - Gloucester

KINGSHOLM STADIUM CHOOSES ELECTRIC INDUCTION COOKING

Target Catering Equipment beat off fierce competition to secure a place supplying and fitting the new fine dining kitchen in the Legends Lounge Restaurant at Gloucester Rugby Kingsholm Stadium.

Gloucester Rugby's finance director and club secretary, John Parker, wanted to upgrade facilities at the club in preparation for Rugby World Cup 2015 corporate entertainment. Several local catering equipment businesses were invited to tender for the works.

After considerable research, the club decided that an all electric kitchen incorporating a commercial induction stove was the answer. Designed, manufactured and installed by Target, the commercial kitchen design utilised to the full the tiny space available and would allow for meals to be prepared and cooked efficiently in house at this famous sports venue.

Along with solving the kitchen ventilation issues associated with the enclosed kitchen, and complying with the fire and saftey regulations at the staudium, Target's energy efficient and safe induction cooking range would once again provide the centre piece for the kitchen.

Target's innovative commercial kitchen design and bespoke manufacture combining induction cooking with a Blue Seal convection oven, rational combi ovens and a balanced air ventilation system proved to be a winning combination at Gloucester Rugby.