Strict Planning Conditions Discharged by Target's In-House Design and Consultancy Team

Target Catering Equipment get local authority Test Valley Borough Council's strict ventilation system conditions discharged for new business's.

Having submitted a planning application for 'Change of Use' from Public House to four units with multiple uses of retail, financial services, restaurant/cafe, drinking establishment with residential flats above, Amici Catering & Co Ltd was granted planning consent for The George Hotel, Andover, subject to conditions back in December 2017.

One of the conditions restricted the listed building from use as a restaurant/cafe by prohibiting the use of cooking equipment such as ovens, grills, chargrills and deep fat fryers except without the use of an approved internal ventilation system.

Ready to move the project forward, Amici Catering & Co contacted Target Catering Equipment as specialist commercial kitchen extraction design consultants to prepare a suitable ventilation system design and specification that would adhere to the planning authorities' requirements.

A main concern was that the property required a ventilation system which could withstand the demands of a commercial kitchen whilst remaining within the property. As found with many listed building, conservation and planning officers stipulate that there must be no changes to the external appearance of the building hence this specific condition being applied.

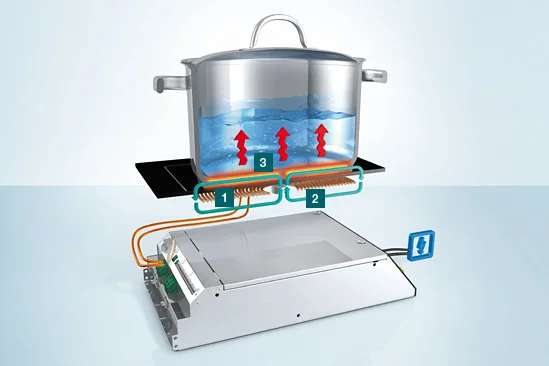

Target designed and specified a complete commercial kitchen ventilation system to suit the proposed kitchen layout and equipment specification. As the kitchen was designed with all-electric commercial kitchen equipment, there was no requirement for a high-level exhaust to atmosphere to dispose and disperse the harmful by-products of combustion and an alternative recirculating option could be implemented.

The system specified uses patented technology that removes particulates and odours and returns air independently certified as clean.

Independent air monitoring specialists, Validair confirms "The air quality from the proposed system is very clean and maintains a level of around ISO Class 7-8 for smaller particles. The larger particles are arrested during cooking periods and for these sizes ISO Class 5-8 is seen.

This means that the air returning from the proposed system unit is around a thousand times cleaner than typical atmospheric conditions."

By specifying this type of recirculating extraction system Target has made a previously unfeasible location for a commercial kitchen within a listed building, into a completely viable option with the condition being fully discharged by the local planning authorities.

5 Points To Consider When Purchasing Stainless Steel Catering Equipment

The right choice of work surface material for food preparation areas in commercial kitchens is crucial in order to prevent the growth and spread of harmful bacteria. Being easy to clean, sterilisable and non porous, stainless steel equipment, such as tables, sinks, shelves and stainless steel kitchen units, are ideal for use in catering, processing, marine and medical industries.

There are several points to consider when purchasing stainless catering equipment, there can be a lot of difference in the price as well as in the quality of stainless steel kitchen equipment, these 5 points should help you make a better informed choice:

There are two main grades of stainless steel used in the manufacture of catering equipment. Grade 430 which is the cheaper stainless steel containing chromium and Grade 304 which is more resistant to corrosion, containing both chromium and nickel, this is more expensive.

Another important consideration when buying stainless steel sinks and tables is the thickness of the steel. A thin guage will not be as durable as a thick one. Top end, very heavy stainless steel is 1.5mm thick, the usual thickness for stainless steel tables and sinks is 1.2mm. It is possible to buy 0.9mm stainless steel but obviously this will not have a long life.

The finish of stainless steel is another factor to consider. For catering equipment that is front of house or on public display such as serveries and counters, highly polished stainless may be used. Satin finish is a fairly dull looking surface which is suitable where the appearance to tabling or sinks is not important and, with its close grain finish, brushed stainless steel is now proving to be popular as it does not show fingerprints so easily. This makes it easier to keep clean than other finishes.

Weak points can occur in the fabrication of stainless steel catering equipment if cheap welding occurs. With 304 stainless steel it is important that 304 stainless welding rods are used to avoid the weld becoming a vulnerable area.

Folding stainless steel increases the strength of the metal and although in the case of pressed sinks, the metal becomes slightly thinner it will actually be stronger.

All Target stainless steel catering equipment is typically manufactured using 304 grade stainless steel sheet as well as 304 grade box section for legs, stands and tie bars. 1.2mm thick stainless steel is used in the construction of tabling, hot cupboards and bespoke stainless steel fabrications. 1.5mm thick stainless steel is used in the construction of sink units and commercial induction worktops. 304 welding rods are used in all Target's welding processes making Target's stainless catering equipment top quality and highly durable.

Target Bespoke Induction Range Wins in Commercial Kitchen 2018 Innovation Challenge

After battling it out against 24 of the latest innovative products developed by a range of market leading brands within the industry, the Target bespoke induction range was awarded as Bronze Winner in the Innovation Challenge 2018. The “Commercial Kitchen - Innovation Challenge” is run by the dedicated foodservice industry trade show Commercial Kitchen and judged by the show visitors along with some of the biggest buyers and innovation experts accross the foodservice and hospitality sectors.

Judges commented “It’s great to see companies like Target bringing new products and bespoke solutions to the market.”

British commercial catering equipment manufacturer, Target Catering Equipment, awarded bronze for innovation in industry challenge.

After a successful debut in 2017, British manufacturer’s Target Catering Equipment returned to this year’s dedicated catering equipment show ‘Commercial Kitchen’, held at Birmingham NEC, with a stand twice the size to showcase their very latest commercial induction products.

Priding themselves on being pioneers in the application of induction technology, Target entered their bespoke induction range into this year’s innovation challenge. Facing a number of market leading brands, Target battled it out on Day 1 to win buyers votes which would result in being put through to Day 2, where they would be in with a chance of winning a coveted Bronze, Silver or Gold award for innovation, following a 90 second pitch to some of the biggest buyers and innovation experts from across the foodservice and hospitality sectors, including; Greene King Kitchen Design and Equipment Manager – Antony Bennett, Star Pubs and Bars Food Strategy and Implementation Manager – Mark Teed and Vision Commercial Kitchens MD – Jack Sharkey, amongst others.

After progressing through round 1, Target delivered their pitch, speaking about how their bespoke induction ranges incorporate the very latest cooking technologies to enable customers to have an edge in the intensely competitive food service industry. How induction technology can reduce power requirements and energy consumption and that new computer-controlled induction generators can be programmed with different power levels and monitored for performance and use giving greater control within kitchens.

They also talked about how system faults within the induction components can be detected and engineers alerted remotely to diagnose potential faults prior to attending site, helping to minimise disruption in the kitchen during busy service times. And how enhanced efficiency improves reliability and life expectancy of the equipment, is important for management, and goes a long way to help in the running of a successful business.

And finally, how each Target bespoke induction range is individually designed and styled to suit the business’s needs and can combine other manufacturers latest cooking equipment therefore delivering the ultimately innovative cookline.

Following all the competitors’ pitches, the judges panel decided to award the Target bespoke induction range with a Bronze award for innovation and commented: “It’s great to see companies like Target bringing new products and bespoke solutions to the market”.

Managing Director of Target Catering Equipment, David Pedrette commented: “We are thrilled to have won a Bronze award for innovation, being a relatively small family business in comparison to many of the other competitors, and British manufacturers at that, it encourages us to continue in what we do, pioneering catering equipment for the future.”

Target were delighted to be one of the only manufacturers of induction cooking equipment to make it to the final and be awarded a Bronze award for innovation, proving bespoke catering equipment solutions are truly innovative.

For more information on any of the products showcased at Commercial Kitchen 2018, or any other products or services provided by Target Catering Equipment, please visit www.targetcatering.co.uk or call +44 (0) 1452 410 447.

English Vineyard Wins Thousands by Switching to Induction

English wine producers, Three Choirs Vineyards, wins over three thousand nine hundred pounds in grant funding by switching to Target commercial induction equipment. Awarded by the Carbon Trust Green Business Fund, for the upgrade of out dated inefficient gas commercial kitchen equipment at their Gloucestershire site to induction, the energy efficient alternative.

With the existing kitchen ventilation system struggling to cope with the waste heat being produced by the LPG gas cookline, combined with the rise in utilities costs, the decision was made to convert the current kitchen equipment to the latest energy saving induction technology.

Assisted by Target Catering Equipment accredited Carbon Trust suppliers, who completed the detailed energy saving assessment, the Three Choirs Vineyards applied for Green Business Funding for fifteen percent of the project cost up to the value of £5,000.

With potential energy saving figures predicted, the Carbon Trust granted the vineyard £3,942.84 towards the new equipment, which included, a bespoke Target commercial induction range complete with induction plancha, induction 4 zone solid top, induction 2 zone hob, twin tank FriFri fryer, Turbofan® convection oven and fast action rise and fall salamander grill.

The Three Choirs Vineyard, Gloucestershire now operates an energy efficient kitchen delivering top quality food with award winning wines.

For more information on the Carbon Trust – Green Business Funding opportunities to reduce energy consumption and costs when upgrading commercial kitchens contact Target Catering Equipment CALL NOW 01452 410 447

Carbon Trust Green Business Funding is limited an available on a first come first serve basis, so don’t delay in getting your application in. It costs nothing, and you could gain up to £5,000 towards the cost of new equipment when replacing in-efficient equipment.

Target Joins Customers To Celebrate Culinary Award Successes

Target feel privileged to have worked with three of this year's award winners, The Best Restaurant, Bangkok Canteen, Gloucester; The People's Choice, The Coconut Tree, Cheltenham; and Best Pub/Bar, The Kilcot Inn, Newent, Gloucester.

The 2017 Taste of Gloucestershire Food and Farming Awards produced a hat trick of customer winners for catering kitchen manufacturer Target Catering Equipment.

Target feel privileged to have worked with three of this year's award winners, The Best Restaurant, Bangkok Canteen, Gloucester; The People's Choice, The Coconut Tree, Cheltenham; and Best Pub/Bar, The Kilcot Inn, Newent, Gloucester.

The Best Restaurant award winner, Bangkok Canteen, opened at the beginning of this year and has already gained recognition from the Sustainable Restaurant Association by being awarded 3 stars; they were also shortlisted for the association's Food Made Good Champion award 2017. Designed and fitted by Target, the kitchen included the very latest 'Food Inspired Technology' including a Target Induction Wok Range. This enables the compact kitchen to produce Thai dishes to perfection in a clean, energy efficient and cool working environment.

Cheltenham's The Coconut Tree offer freshly produced Sri Lankan street food and was the winner of The People's Choice award. Having recently opened, their kitchen was designed and installed by Target who helped the owners squeeze sufficient catering equipment into their small kitchen to allow them to create a more productive working facility.

The hat trick of winners was completed with the Best Pub/Bar award being won by The Kilcot Inn situated near Newent in the Forest Of Dean. The Kilcot Inn had its kitchen fitted out by Target when it was completely renovated several years ago, it provides fabulous food cooked using local produce alongside a selection of real ales and local ciders.

Specialising in energy efficient induction cooking ranges and equipment Target takes pride in delivering sustainable kitchens for commercial kitchens across the UK. All the kitchens are individually manufactured in house at the Target factory located in Gloucester.

Target are delighted to be able to support local catering businesses and congratulate their customers on their award successes.

Taste of Gloucestershire 2017, Best Restaurant Winners - Bangkok Canteen, Gloucester

Taste of Gloucestershire 2017, The People's Choice Winners - The Coconut Tree, Cheltenham

Taste of Gloucestershire 2017, Best Pub/Bar Winners - The Kilcot Inn, Newent

Guide to Commercial Plancha Cooking

Having recently introduced the commerical induction plancha as a bespoke induction range configuration option, Target brings to you a guide on plancha cooking, explaining the differences between electric griddles, electric planchas and induction planchas.

THE DEFINITION OF 'PLANCHA COOKING' IS, TO COOK FOOD DIRECTLY ON A HOT OILED PLATE.

Induction Plancha

Electric Griddle

Electric Plancha

All three pieces of equipment listed above are typically hot metal plates used to cook food directly on. The type of metal plate will vary from each manufacturer of product, with each having different conductivity characteristics.

Heating Technology

How the hot metal plate is heated will affect the characteristics of the plate surface, resulting in different outcomes when cooking.

Electric Griddle

The electric griddle most commonly uses rod elements for heating the griddle plate surface. This type of electrical element is the slowest to react to change in temperature setting and can deliver inconsistent surface temperatures, with hotspots where the element is directly below or in contact with the metal surface.

Electric Plancha

The electric plancha or French plancha, as it is sometimes called, typically uses a filament element for heating the plancha plate surface. Filament elements tend not to cover the entire surface of the plate and rely on heat dispersion to distribute heat across the surface. This results in graduated temperatures from hot to cool from the middle to the edge of the plancha cooking surface, a characteristic similar to the gas solid top.

Heat up times of the electric plancha from 20°C to 230°C takes approx. 20-30minutes. However, this temperature would not be consistent across the entire plancha plate.

Induction Plancha

The induction plancha uses the same type of coil elements as used with induction hobs. The induction coil element covers the entire plancha plate surface, optimizing operational efficiency by providing uniform heat distribution from corner to corner.

The speed of temperature control depends on the composition of metal used in the plate surface, however, is by far the fastest out of the three equipment types. The instant energy transmission from induction coil to plancha plate surface allows for fast start up times, for example;

The commercial induction plancha used in Target induction ranges heats up from 20°C to 230°C in just 4½ minutes on the single zone 3.5kW induction plancha and just 3 minutes on the single zone 5kW induction plancha.

Temperature Monitoring & Recovery

For consistent cooking precise temperature monitoring is required.

Electric Griddle

Electric griddle plates are typically manufactured from mild steel which is a cheaper material when compared to chrome plated steel or composite stainless steel. Mild steel has relatively poor conductivity properties and therefore is affected when cold produce contacts the surface, fluctuating cooking temperatures.

The rod elements used for heating the plate are thermostatically controlled and regulate the temperature of the cooking surface. Temperature regulation is electro mechanical, with a poor degree of accuracy and reactiveness, which results in users having to move product around the griddle as temperatures vary across the grill plate.

Electric Plancha

Quality electric plancha plates are manufactured from thick steel, this maximises thermal retention and minimises fluctuations in surface temperatures when cold produce contact the surface. However, the use of thick steel reduces the conductivity which means heat up and temperature change times are prolonged.

Surface temperatures are monitored using a temperature probe, situated between the plate and the element. However, the probe is usually unable to read the temperature at the centre of the element where it is hottest and can therefore be unreliable when it comes to temperature control.

The heat retention characteristics of the plancha plate minimises fluctuations in the surface temperature, therefore, there would need to be a dramatic drop for the probe to detect a change and bring the plate back to the temperature it was set at.

Induction Plancha

The commercial induction plancha plate is a composite of different metals. The induction plancha plates that are used in Target ranges are made up of steel and aluminium. Joining the magnetic characteristics required for use of induction technology with the heat conductivity characteristics found with aluminium. Combined, results in fast heat up times and rapid temperature control.

Having a thinner metal plate means the cooktop is more susceptible to plate temperature change, which occurs when cold food is placed on the plate, however this can be overcome with the use of RTCSmp® (Real-Time Temperature Control System Multi Point) providing precise temperature monitoring across the entire cooking surface.

RTCSmp® uses multiple sensors embedded across the plancha plate surface to detect a deviation in temperature as small as one-half degree, the temperature is then automatically adjusted in that specific area, providing a highly consistent, responsive, surface to cook on.

Not only does the RTCSmp® regulate the temperature of the cook zone, the technology also monitors continuously in real-time, the energy supply and the state of the components such as the induction coil. Should a malfunction occur, the integrated fault diagnostic system reports the malfunction instantly to the user.

Correct Operation

Although seemingly similar to a solid top appliance, all three pieces of equipment featured in this guide are intended to be used for cooking produce directly on, without the use of a pan.

By using a pan on any of these pieces of equipment you run the risk of creating hot spots on the plate as heat can be conducted back into the surface which can cause plates to warp and can also create malfunctions in the technology systems beneath.

For those looking for an energy efficient alternative to the gas solid top, where multiple pans are to be used for cooking, a graduated slide top induction hob with single control is the best like for like option currently available on the market from Target Catering Equipment.

Overview

The electric griddle offers an appliance with a surface that delivers inconsistent temperatures across the plate with long heat up times and provides limited temperature controllability.

The electric plancha surface delivers gradient temperatures from the centre to the edges of the plate, suitable for varying product finishes. The plate characteristics result in longer heat up and temperature change reaction times.

The commerical induction plancha surface delivers consistent temperatures across the entire plate surface, suitable for cooking quantities of produce to the same finish. Heat up times are minimal, and controllability is highly reactive.

Tewkesbury Garden Centre Goes Green!

Thumbs up from Head Chef at Tewkesbury Garden Centre as owner Rachel Gallagher receives almost four thousand pounds Green Business Funding from the Carbon Trust to improve the restaurant's kitchen equipment making it more energy efficient and user friendly as the business continues to grow.

Famed for using local food produce and suppliers the garden centre restaurant goes from strength to strength, now working with local manufacturer and Carbon Trust accredited supplier Target Catering Equipment to provide the new kitchen equipment.

With the help from Target Catering Equipment Rachel was able to submit an application and prove to the Carbon Trust that switching from the existing electric hotplate hobs and basic electric oven to a Target six zone induction range with Blue Seal Turbofan ® convection oven would be more energy efficient and sustainable for the business. This in turn lead to the Green Business Funding capital contribution being awarded.

The small kitchen can now keep up with customers' demands, and with a team of dedicated staff, can continue to produce quality local farmhouse food.

For more information on the Carbon Trust - Green Business Funding opportunities to reduce energy consumption and costs when upgrading commercial kitchens contact Target Catering Equipment CALL NOW 01452 410 447.

Carbon Trust Green Business Funding is limited and available on a first come first serve basis, so don't delay in getting your application in. It costs nothing and you could gain up to £10,000 towards the cost of new equipment when replacing in-efficient equipment.

Target Turns Westbury Worries Into Wins!

Westbury Village Hall grows with Carbon Trust funding to upgrade condemned kitchen.

Westbury Village Hall grows with Carbon Trust funding to upgrade condemned kitchen.

Westbury Village Hall, home to many local sporting clubs and associations, has won over £900 of equipment funding from the Carbon Trust. With existing gas fired kitchen equipment having been condemned, the committee decided to invest in the very latest energy efficient induction cooking technology, British manufactured by Gloucestershire based Carbon Trust Accredited Suppliers, Target Catering Equipment.

"The gas kitchen was struggling to cope with the growing demands of the hall. Having been condemned due to the latest gas safe regulations we weighed up our options and, as advised by Target, decided to apply for the Green Business Funding Scheme to see if we could get a capital contribution towards the induction cooking equipment we dreamed of." says Westbury Committee Member and Project Manager Jan D'Ambrogio.

The Carbon Trust Green Business Funding Scheme offers businesses and community groups up to £10K towards energy efficient equipment and is available to SMEs for a limited time only. Capital contributions are based on the current energy usage and potential energy savings that could be made through switching to energy efficient equipment.

"With the help of Nicola Pedrette, Target's Carbon Trust Funding Advisor, we were able to demonstrate the significant savings that would be made by switching from gas to induction and we were awarded over £900 capital contribution to our project." commented Jan.

Now, with the new equipment in place, the village hall is fast becoming known as one of the best community run facilities within the county and is attracting more and more events and organisations. It has already successfully hosted Westbury United Football Club's annual dinner and presentation evening and is said to be one of the best indoor short mat bowls venues in the county. It is clear the community venue is growing from strength to stength with its recent investments in sustainable cooking technology.

"We are delighted that Westbury Village Hall has been awarded the funding from the Carbon Trust and that we have been able to help in this process, although only a seemingly small contribution in comparison to other businesses running commercial kitchens 24/7, it has undoubtedly helped a community hall, local to us, achieve a facility for the future." says Target's Carbon Trust Funding Advisor, Nicola Pedrette.

For more information on the Carbon Trust Green Business Funding please call 01452 410447 or visit Target Catering Equipment on stand J34 at the Commercial Kitchen Show 6th - 7th June 2017 at Birmingham NEC.

Commercial Kitchen Show 2017 - Target's Innovative Induction Makes Its Debut

British commercial catering equipment manufacturer, Target Catering Equipment, is to showcase latest induction products at this year's Commercial Kitchen Show.

British commercial catering equipment manufacturer, Target Catering Equipment, is to showcase latest induction products at this year's Commercial Kitchen Show.

British manufacturers Target Catering Equipment debut at this years’ Commercial Kitchen Show, and invite visitors looking to improve sustainability within their commercial kitchen to stand J34 to see two of their very latest commercial induction products; the Target Restaurant Range with induction plancha, and the T8-2 Zone induction wok range. Visitors will also have the opportunity to discuss the free funding opportunities being provided, for a limited time only, by the Carbon Trust when upgrading to energy efficient equipment.

Managing Director, David Pedrette commented: “We are thrilled to announce that we have chosen the Commercial Kitchen Show as our exclusive national exhibition of choice. To have an industry show dedicated to commercial catering equipment gives us, a small British manufacturer, a central platform to showcase our products to the ‘who’s who’ of the equipment buying world from across the UK.”

Providing an energy efficient alternative to the traditional 6 burner gas range or solid top, the Target commercial induction Restaurant Range, built as a standard item with varied combination options, brings to the marketplace an ‘off the shelf’ appliance with added customisability.

The standard Target Restaurant Range features the very latest induction plancha, combined with 4 zones of 3.5kW heavy duty induction and E31D4 Blue Seal convection oven. Combination options include; E32D4 Blue Seal convection oven, Adande refrigerated drawer under, height adjustable under shelf, over shelf and fast action rise and fall salamander grill.

The Target T8 Induction Wok Series is due to be launched later in 2017, however on stand J34 visitors get a preview of the T8-2 Zone, a heavy duty 13.5kW 2 zone induction wok range with added flat induction stockpot zone, sink with tap and waste strainer, which incorporates newly developed DualCool® technology, designed to enhance the performance of induction specifically for the oriental foodservice sector.

As accredited Carbon Trust suppliers Target invites SME businesses looking to upgrade inefficient catering equipment to the latest energy saving technology to find out about the 30% free capital contribution opportunities available from the Carbon Trust – Green Business Fund Scheme.

For more information on any of the products being showcased at the Commercial kitchen Show 2017, or any other products or services provided by Target Catering Equipment, please visit www.targetcatering.co.uk or call +44 (0) 1452 410 447.

Visit Target Catering Equipment on stand J34 at the Commercial Kitchen Show 6-7th June 2017 at Birmingham NEC.

The Advantages Of Using Induction Hobs

The Advantages Of Induction Hobs

Gas hobs have long been the first choice for professional kitchens all over the world. However in recent years we've seen an increasing number of foodservice establishments across the UK and Europe adopting the induction style of cooking. This method of hob based cooking is not only limited to homeowners, but professional kitchens are choosing to incorporate induction hobs into their new kitchen designs, here's a quick rundown of just why this type of cooking is becoming increasingly popular.

Speed - The process of induction means that the pan heats up much more quickly than with gas or electric radiant based cooking. Induction hobs work by using electromagnetic currents in the cooktop to trigger electromagnetic activity in the pan, so the pan effectively heats itself up without the middleman ie. flames. This means less time waiting for things to heat up so therefore the food can be cooked quicker. In a restaurant environment this means much quicker service and happy customers.

Energy efficiency - With the pan heating itself up more of that heat can go directly to the food, gas and electric hobs give off radiant heat which heats everything around them. In a professional kitchen environment this means a lot less radiant heat is emitted during cooking; a cooler kitchen means happier, more efficient chefs! Induction hobs are a much more energy efficient way to cook due to the reduced energy consumption that also comes with quicker cooking.

Safety - The hob area can be one of the most dangerous places in the kitchen whether a domestic one or a professional one. Induction hobs are much safer than gas or electric radiant hobs because it is the pan, and the product within that gets hot rather than the stove. No flames means no accidental fires, and no gas means no gas leaks.

Control - Professional chefs have always preferred gas stoves over electric as gas is much more responsive when you turn it up or down. Induction hobs are just as, if not more responsive as gas hobs when the temperature is increased or decreased. In fact, induction cooktops allow better control with smaller temperature increments and better performance at low temperatures so it's much easier to keep things warm without burning or overcooking them.

Cleaning - The fact that an induction hob doesn't get hot (other than from the heat of the pan) means that food residue doesn't burn onto the cooktop. A spillage just calls for a quick wipe rather than an intense scrub and can be done whilst in use. The surface of induction hobs are completely flat too so it's incredibly easy to wipe over compared to gas or electric radiant hobs with bits that detach and protrude!

Asian Restaurant Kitchens - It's Out with Tradition!

Target's Managing Director, David Pedrette, discusses why traditional Asian Oriental kitchens need to evolve in order to be successful.

Producing commercial kitchens for almost 30 years, Target Catering Equipment has seen many changes within the Asian Oriental Cuisine sector and experiences on a daily basis the hurdles that the industry is faced with, whether it's restrictions from local councils, staffing issues or energy costs. As equipment manufacturers and design consultants, it's Targets job to find solutions to overcome these issues. Here, Target's Managing Director, David Pedrette, discusses the future of Asian Oriental kitchens.

Asian Oriental cuisine is a favourite on British high streets, however, is fiercely competitive, with an estimated two businesses closing down each week, business owners are always looking at ways to increase profit and maximise output, without compromising on quality and consistency. There are many factors which contribute to the success of an Asian Oriental business many of which can be found inside the kitchen.

Gone are the days when businesses started up on a shoestring with minimal regulation and compliance issues, using a mix of used, second hand affordable equipment that was unregulated and inefficient, usually hived off from kitchen refurbishments and rescued from the scrap yard.

As a result of lack of regulations over the years high streets have become overcrowded, with rental and business rated climbing businesses now have to consider smaller premises. With this comes the challenge of installing a working kitchen that makes the most of the available space, is efficient and does not compromise the quality of the finished product.

Planning Your Commercial Kitchen -

Kitchens must be compliant to all regulations and restrictions; with modern regulations becoming ever more stringent and governing bodies carrying out regular checks to regulate compliance, sourcing equipment which complies with regulations is a major factor.

The amount of regulations you are required to comply with starts with the type of fuel you decide to use within the kitchen. Traditionally, gas has always been the favoured fuel within the Asian Oriental market. however, with the recent development of commercial induction cooking technology there is now a more powerful, controllable and efficient alternative to gas, which is not burdened with the regulations as attached to gas equipment.

With all electric commercial kitchens, ventilation systems become smaller, more efficient, cheaper to install and maintain. Regulations are minimised meaning compliance with local authority regulations and DEFRA requirements becomes easier.

One of the major stigmas that are linked to working in an Asian Oriental kitchen is the environment. When using gas fired open burners, Asian Oriental kitchens are amongst the hottest commercial kitchens to be working in. However, when induction technology is used, there is no waste heat being given off into the atmosphere, all the heat and energy goes diectly into the product in the pan, resulting in a substantially cooler kitchen for chefs to work in.

Induction technology also dramatically reduces fuel costs, not only do you remove the waste heat from the kitchen, energy is only consumed when the pan is on the hob. With instantaneous heat, burners do not need to be left on to heat up, minimising energy consumption, reducing fuel costs and speeding up cooking times.

With the number of fully trained, qualified, Asian Oriental chef's rapidly depleting, running a business and kitchen which attracts the best staff has never been more important. This continual lack of skill has inevitably resulted in the decrease in qualtiy of end product thus over the years resulting with the negative reputation that the industry is often tarnished with by younger generations.

In order to remove the stigma that comes with working within the Asian Oriental industry working conditions and tradition has to change, it's time to embrace modern technology.

Business owners are now able to employ staff that may lack in skill, whilst remaining certain that the end product will not be compromised, and will be of a consistent quality no matter which chef is in the kitchen purely by implementing automation and programming into cooking processes. These easy to use systems are more often image controlled and are therefore easy to use by people of varying ethnicities, without any confusion, thus addressing the ongoing crisis of lack of skilled staff, giving head chefs the opportunity to expand their skills and develop menus trying out new ideas with the kitchen.

Once the equipment has been chosen it's important to get the right layout. Having the correct layout will ensure flow within the kitchen and minimise the possibilities of cross contamination.

This is the secret to business success, getting the right equipment and systems in place to optimise output without compromising quality while delivering great service and hospitality in comfortable on trend surroundings.

Target's 5 Top Tips:

Make sure your kitchen complies with the latest regulations

Consider which type of fuel will be best for you

Trial equipment before making decisions

Think about long term running costs

Invest in your business at the start for long term success

Target Awarded Accredited Supplier Status for Carbon Trust Green Business Funding

Having been independently assessed by the Carbon Trust and exceeded criteria designed to examine capability and proven track record of delivering thoughtful, well-designed energy efficient and renewable energy systems, Target Catering Equipment has been awarded accredited supplier status.

Target Catering Equipment accredited by the Carbon Trust in recognition of their track record in designing and delivering high quality catering equipment solutions.

Having been independently assessed by the Carbon Trust and exceeded criteria designed to examine capability and proven track record of delivering thoughtful, well-designed energy efficient and renewable energy systems, Target Catering Equipment has been awarded accredited supplier status.

The Carbon Trust Accredited Supplier scheme is the market-leading scheme for high quality energy efficient equipment and renewable technology suppliers. As part of a robust assessment process, the Carbon Trust takes into consideration a number of case studies, and feedback from client references regarding the suppliers' performance, providing business owners' with independent validation and recognition of a supplier's skills and services.

The Green Business Funding scheme is designed to assist small and medium businesses that are looking to upgrade inefficient catering equipment to the latest energy saving technology by offering a free financial contribution of 30% of the project cost (up to a max. of £10,000).

This support is available for a limited period and is on a first come first serve basis to businesses with fewer than 250 employees. Minimum total project cost must be £2,500 and equipment should be purchased from a Green Business Directory supplier such as Target Catering Equipment.

Along with a financial contribution the Carbon Trust also offers businesses an energy opportunitiy assessment, implementation advice, equipment procurement support and workshops.

To find out more about the Carbon Trust Green Business Funding opportunities visit https://www.carbontrust.com/client-services/technology/implementation-and-finance/green-business-fund/ or speak to Target Catering Equipment for advice on the latest catering equipment technology and energy saving solutions that can be funded through the Carbon Trust Green Business Fund. Call now on +44 (0) 1452 410 447.

Target and Frima Send Heavenly Help to The Angel Inn

Gloucester-based Target Catering Equipment has redesigned and outfitted a new kitchen for The Angel Inn at Upton Scudamore, Wiltshire. The hotel and restaurant's kitchen was refurbished to reflect and deliver a blend of contemporary and traditional styles, it was therefore decided that the Frima VarioCooking Centre would be the appliance of choice.

Gloucester-based Target Catering Equipment has redesigned and outfitted a new kitchen for The Angel Inn at Upton Scudamore, Wiltshire. The hotel and restaurant's kitchen was refurbished to reflect and deliver a blend of contemporary and traditional styles, it was therefore decided that the Frima VarioCooking Centre would be the appliance of choice.

As much as possible, Head Chef Adam Clayton makes everything in house, from bread to mayonnaise, so the equipment in the kitchen had to be reliable and multifunctional..exactly what the Frima VarioCooking Center is about.

The 112T is the first tabletop model of its type, the 112T combines the functionality of a wide range of conventional appliances while its size allows it to be used in smaller kitchens that larger multifunctional models.

The Angel Inn's Head Chef comented:

"I will admit, at first I was a bit sceptical that it could do everything it was supposed to, but now we've had it for a while we're really happy with it".

"It's very versatile. I can use one pan to make stocks and sauces, while the other side cooks meat."

Despite measuring just 962mm wide by 800mm deep and 400mm high, the 112T has two 14 litre pans, giving it the same capacity as its larger sibling, the VCC 112. It can replace kettles, tilting pans, bratt pans, fryers and griddles, and its clever technology it contains means it's up to four times faster and saves up to 40% in energy consumption compared to conventional appliances.

The cooking processes are automatic and fully monitored by built-in VarioCooking Control system with notifications for when user input is required, allowing even delicate ingredients to be cooked easily.

Clayton added:

"The temperature control is great. If you want your meat and fish to be seared and browned to a certain colour, it comes out the same every time."

"We now have an all-electric kitchen, no gas at all. The 112T heats up so quickly, so there's no need to have the burners on all the time. The kitchen is much cooler now, plus it saves energy and money."

It's also simple to clean and maintain.

"It's got the built-in water hose, so you can clean it as soon as it's finished," says Adam, "Plus it's mounted on wheels, so we can easily move it to clean around it."

With an average of 60-70 covers a day during the week and as many as 120 at the weekends, the 112T has become an invaluable addition.

"It saves us a lot of time - it now takes just an hour to prepare a batch of soup, for example, and there's no need to keep an eye on it. Just start it off, and once the program is complete the food is ready to go."

Target Leads the Way with Innovative Catering Equipment

Target Catering Equipment announced as winners of the Gloucestershire Business Show 2016 award for ‘Innovation in Business’. As trail-blazers within the foodservice industry, Target Catering Equipment have worked tirelessly over the past 8 years to change business owners and chefs’ perceptions of commercial kitchens across the UK, through the development of innovative catering equipment.

Target Catering Equipment wins Business Show Innovation Award for changing perceptions of commercial kitchens.

Target Catering Equipment announced as winners of the Gloucestershire Business Show 2016 award for ‘Innovation in Business’. As trail-blazers within the foodservice industry, Target Catering Equipment have worked tirelessly over the past 8 years to change business owners and chefs’ perceptions of commercial kitchens across the UK, through the development of innovative catering equipment.

“If you can’t stand the heat keep out of the kitchen” used to be the saying but with Target Catering Equipment’s innovative approach to developing technology, this is no longer the mantra of chefs.

“Need - is the mother of invention and innovation” Recognising that cooler more efficient kitchens were needed by business owners, in order to minimise overhead costs, improve working conditions and attract the best chefs to work in their commercial kitchens, Target began research and development into commercial induction cooking equipment which had previously been written off by larger manufacturers, preferring gas for speed, controllability and cheap manufacturing costs.

With the Government also striving to reach Kyoto 2020 energy reduction and reduced carbon footprint targets, commercial kitchens have been regarded as high energy consumers with massive energy waste and increased carbon emissions that are now under increased scrutiny by the Carbon Trust who have continued to implement new initiatives to reduce energy consumption, and waste and increase renewable energy supplies.

Through Target’s continued development and ability to custom manufacture equipment to suit individual requirements, induction cooking technology is now considered by many within the industry as one of the best forms of cooking technology. Businesses making the decision to invest in the latest innovative catering equipment are seeing the instant and long term benefits of becoming a more sustainable and efficient business.

Gloucestershire is becoming a hub for green energy innovation design and development with many other specialist businesses located to the area. Target Catering Equipment continues to develop new ideas and technologies within the foodservice industry combined with other leading European manufacturers of equipment, and anyone who is interested in improving their business by investing in the latest innovative commercial kitchen equipment should contact Target.

Plancha Cooking with Celebrity Chef Emily Watkins

See how Celebrity Chef Emily Watkins of The Kingham Plough creates her BBC2's Great British Menu winning dish 'Fight Them On The Beaches' using Target Catering Equipment induction hob and French plancha.

Staying on Your Feet: How to Choose Commercial Kitchen Flooring

A good commercial kitchen needs solid foundations, so where better to start than the flooring. Design Consultant Nicola Pedrette of Target Catering Equipment, reveals the four key rules to getting it right underfoot.

Of all the areas of your commercial kitchen, flooring is one of the most important. Any food or drink that gets spilled onto it can turn into a death trap for your staff. Spillages can lead to people slipping over, and if they're not cleaned up straight away they can become a breeding ground for bacteria. Dirt and bacteria already make their way into your kitchen via the shoes on the feet of your staff, so it's important to do everything you can to minimise the risks. When it comes to purchasing flooring for your kitchens there are several things you should take into account...

1. Slip resistance - Commercial ktichens get busy and chaotic at peak service times, with lots of staff trying to move around all at once. All of that hustle and bustle, accompanied by food, grease and water on the kitchen floor, can lead to it becoming a serious slip and trip hazard. Slip-resistant flooring is absolutely essential in any professional kitchen in order to minimise and control the risk of your staff slipping and injuring themselves.

2. Practicality - Safety and practicality should be at the forefront when you're thinking about what flooring to purchase. For example, a tiled floor can easily chip and crack with the constant heavy use associated with a commercial kitchen. This then opens up more nooks and crannies in which bacteria can hide and grow. Flooring that is durable, not prone to cracking and ideally in one piece without seams is ideal for you kitchen.

3. Maintenance - Easy-to-clean flooring is ideal in a catering kitchen setting as spillages need to be dealt with as quickly as possible so as not to disrupt service too much. Slip-resistant epoxy or vinyl flooring is easy to clean and doesn't provide cracks for food and other debris to get caught in. This means that from a maintenance point of view, it can be swept and mopped much more easily.

4. Durability - Changing the flooring in your industrial kitchen every two to three years is a real hassle so it's important to look for flooring that offers excellent durability and will stay the course. A slip-resistant, easy-to-clean, durable floor might appear to cost more in terms of initial outlay but it will save your organisation money, time and hassle in the long run.