The Pizza Planet - Cam, Dursley

The Pizza Planet - pizza, burger and wrap takeaway shop originally opened in Cam, Gloucesterhsire in 1998. Following year on year profits generated by the succesful quick service takeaway restaurant, owner Mr Yavari was able to re-invest in his business and as a result set up three further ‘The Pizza Planet’ franchise takeaway restaurants. In 2019, the unit next door to the Cam restaurant which was previously operating as a beauty salon became available, Mr Yavari jumped at the opportunity of acquiring the property with the view to expanding his flagship site.

After 21 years in business, the entire takeaway shop and kitchen in Cam was well overdue a refurbishment. This meant that the expansion into the next door unit had come at just the right time as now both the refurbishment and expansion could be combined. Mr Yavari’s main aim for the expansion and refurbishment, was not to increase throughput and profit, but to improve the working environment for his staff, many of whom had proved themselves to be loyal and hardworking employees having worked at The Pizza Planet for many years.

PROJECT BRIEF

The existing quick service restaurant was extremely tired and worn, overall the layout of the takeaway kitchen was compact and struggled to house all the equipment, ingredients and consumables required to keep up with demand and as a result made it difficult for staff to operate safely and efficiently.

Walls, floors and ceilings needed replacing, as maintaining a high level of cleanliness on damaged surfaces proved an almost impossible task for kitchen staff.

The heavily used gas fired kitchen appliances including conveyor pizza oven, griddle and fryers in the small kitchen space generated excessive amounts of surplus heat. Combined with a dated extraction system not operating effectively, with minimal fresh air supply, made for an insufferably hot kitchen especially in summer months.

With an idea in mind, Mr Yavari decided to contact Target for assistance on the project. Having worked together with Target’s MD David Pedrette many years prior when Mr Yavari was setting up his first ever UK based takeway business, he was confident that David and the team at Target could deliver the quality end result that he was looking for.

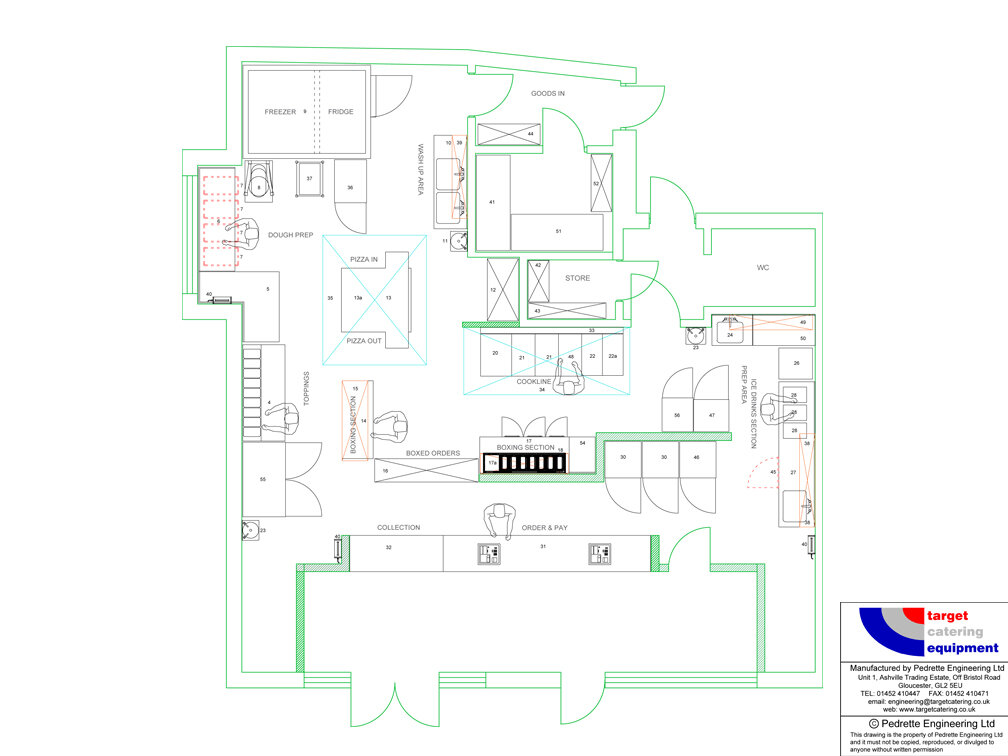

After an initial consultation to discuss his requirements for the business, and a full site survey, Target’s designers David and Nicola set to work to prepare a suitable commercial kitchen layout and ventilation system design for the soon to be expanding flagship site.

Key factors to be considered in the design were;

Improved Working Environment

Workflow & Efficiency

Health & Safety: Hygiene, Cross-Contamination etc.

Re-use of “Good” Existing Equipment

Increase Storage Space

THE PROCESS

The kitchen layout was designed specifically to allow for maximum space and a clear flow from start to finish for each cooking process; pizza production, grill and fried product production and beverage production which in turn would minimise crossover of staff from each area including back of house kitchen staff and front of house service and delivery staff. This also meant the front of house order, delivery and collection systems could run more smoothly without interuptions.

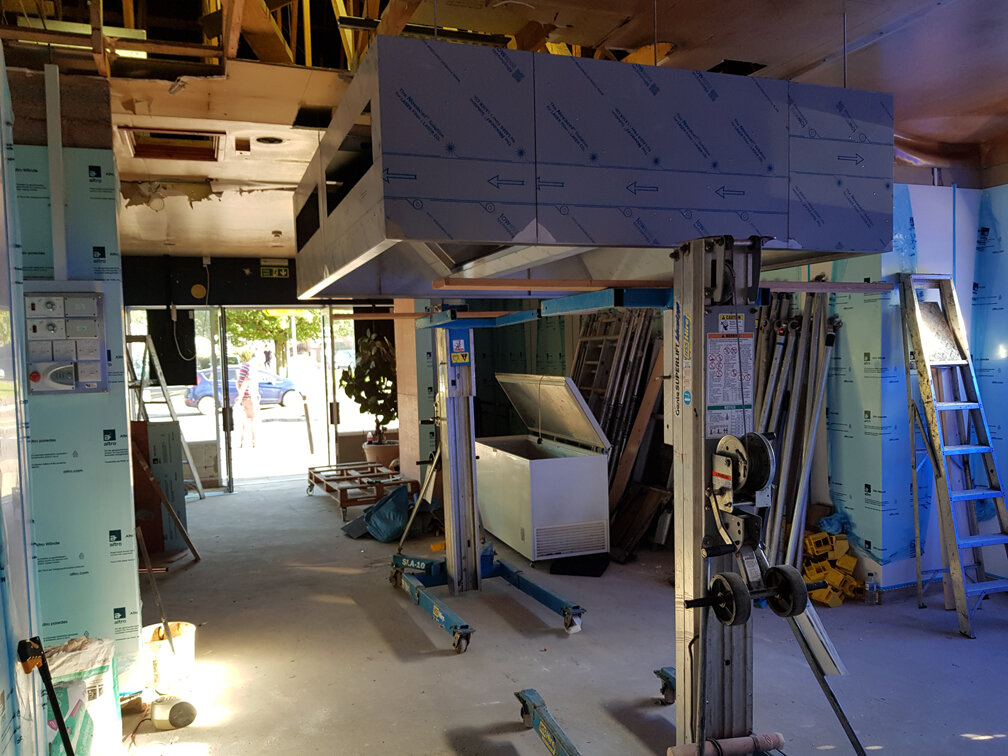

Once the kitchen layout design prepared by Target had been agreed and signed off, the transformation process could begin. The project involved knocking through two units to create one larger space. Mr Yavari’s team set about stripping out the exisitng store units in order for contractors to carry out building works, m&e electrical and plumbing upgrades and fitting of new Altro hygienic surface fininshes to walls floors and suspended ceiling. Everything including the existing extraction system was taken out to be replaced, with some equipment being serviced and re-used in the new commercial kitchen scheme.

With a tight schedule to meet, whilst building works on site were getting underway, Target set to work manufacturing bespoke stainless steel items ready for installation of equipment in the following weeks.

The new equipment to be installed included; Hoshizaki Gram refrigeration prep counters, Middleby UK conveyor pizza oven, Blue Seal griddle, fryers and chip scuttle, Target prep and packaging benches, sinks, gantries and service counter, and Fosters walk-in refrigeration.

THE END RESULT

“Working with Target completely transformed the business” said Yavari. “Having worked with other suppliers previously, it was a pleasure working with one of the best again having enjoyed a relationship with David Pedrette MD of Target since the opening my first joint venture shop in Gloucester back in the 1980’s when I arrived in the UK following the revolution in Iran and David was an installer for a local catering equipment manufacturer in Gloucester.”

When the business reopened in September 2019 following the complete refurbishment and rebrand, who would have known the Covid-19 pandemic was lurking around the corner in 2020. The Covid-19 pandemic has proved to be catastropic for many food busineses but following a year of trading during these difficult times, Mr Yavari states he has seen at least a 20% increase in business as a result of being able to continue trading as the business was so simply and easily able to conform with the Government guidelines of sanitation, separation and flow within his shop, with in and out customer doors and simple service counter screens, along with all the regular sanitation measures put in place.

To discuss your refurbishment project with Target Click Here.