WARRANTY: Commercial Induction You Can Rely On!

Target commercial induction ranges are manufactured in the UK using quality European induction components.

Designed for heavy duty commercial use Target commercial induction is fully supported with a 3 year parts and labour warranty.

Target Commecial Induction Hobs

All Target induction hobs and induction wok hobs sold in the UK and Ireland are covered by a three-year commercial use (26,280 hrs) on site parts and labour manufacturers warranty. Giving you peace of mind, that even if you are using your Target induction hob 24hrs a day for 3 years, your product will be covered should any problems arise and you won't have to pay for any repair or replacement during this period*.

Exceptions to our warranty terms include consumable items such as control knobs, filters, bulbs and glass. Full details of our warranty terms can be viewed here.

Overseas sales are covered by a three-year parts only warranty, excluding spare parts and consumable items.

Please note that appliances, other than induction hobs which are built into Target commercial induction ranges (i.e. griddles, fryers, planchas, ovens etc.) will have a seperate manufacturers warranty.

(*Subject to warranty terms - View here)

FAQ'S: Target Commercial Induction

How much is induction?

The initial capital outlay of an induction range is dependent on quality and configuration of the appliance and can vary, for example, from a couple of thousand pounds for a mass-produced range to tens of thousands of pounds for a custom-built bespoke suite. Custom made cooking suites are typically more expensive than off-the-shelf mass-produced units as they are designed specifically to suit your kitchen’s requirements and are manufactured and finished to higher standards, using a superior and wider variety of components. However, they are designed and manufactured to optimise the chef’s performance within the kitchen, making kitchens work smarter and faster, not harder, by using the very best combinations of equipment to suit their own specialist and individual cooking techniques, which in turn generates more profit for the business.

Is induction as powerful and controllable as gas?

Independent tests have shown cooking with induction to be much faster than gas. When heating equal quantities within a pan, an induction hob uses less power (kWhs) than gas to complete the same task within a shorter space of time, therefore making induction a more powerful, effective, and efficient method of cooking when compared to gas. This is because with induction cooking technology the pan acts as the heat source rather than the flame or heating element underneath it. With gas, you can easily vary the size of the flame which alters the convected heat and allows the pan to heat up or cool down accordingly to achieve the in-pan temperature you require. With induction, the temperature within the pan is controlled with rotary controls which varies the electromagnetic current which in-turn instantaneously alters the temperature generated within the pan making induction much more controllable and accurate.

What’s the difference between a circular induction coil/zone and a square coil/zone?

Square coils/zones provide a larger surface area to use, perfect for cooking with smaller multiple pans. Circular or round induction coils/zones replicate traditional round gas burners and are ideal for larger individual pans and stock pots. If you use multiple pans on a circular zone where the pans only partially cover the coil beneath the glass hot-spots can be generated at the edges of the coils, delivering un-even cooking temperatures in the base of the pans. For more information on induction coils/zone types click here.

Can I use induction like a gas solid top?

Yes, this is achieved by using square or rectangular coils/zones. These can be positioned together beneath a piece of glass creating a larger cooking surface area that replicates the gas solid top. The square or rectangular zones can then either be controlled by individual controllers per zone for variable temperature control or each zone can be pre-set by the manufacturer at varying powers with all the zones controlled by one controller providing a cooking surface with a gradient heat “slide top” effect. The benefits of having variable controls is that you have either 2 or 4 controllers and if one controller fails you can keep the other zones working with minimal interfereance until the failed controller is repaired or replaced. If there is a fault with the single controller on the “slide top” solid top style induction hob each zone would stop working and you would loose functionality of the entire cooking surface until the controller is repaired or replaced.

What’s the difference between heavy duty, medium duty and light duty induction products?

The main differences between heavy, medium and light duty induction products are;

1) Length of Warranty Cover - Each product will be supplied with a certain amount of warranty cover given by the manufactuerer, the length of warranty cover is typically determined by the expected servicable length of duty cycle when a product is run at full power. Product components are designed to operate effectively at least for this length of time without any faults. Should a fault occur within this period this would be unexpected of that component and therefore would be covered by the component manufacturers warranty.

2) Quality of Induction Components - The better quality of induction components, the stronger your product will be. When used in a busy commercial kitchen a product’s induction components will need to be hard wearing to withstand the daily hammering of constant use in a commercial kitchen. With better quality induction components, your product lifetime will be longer.

3) Power Output Voltage - Induction with a higher power output means larger pots and pans can be used and will heat up quicker. Light duty products typically have low power outputs and therefore cannot cope with larger pots and pans.

4) Component Cooling Allowances and Technology - Required to ensure the appliance components can handle higher demand usage - Induction components have a optimum operating temperature, when a appliance is being used heavily it will require additional cooling technology to reduce the risk of components failing.

What power supply do I need for a Target commercial induction range?

Target commercial induction ranges can use both single phase 230 volt generators and 3 phase 400 volt generators depending on cusomer's specification and electrical supply capacity.

What access do I need to allow for getting my Target commercial induction range into my commercial kitchen?

Target standard induction products are designed to fit through a standard 830mm wide doorway. For deeper units or smaller entry points, bespoke ranges can be manufactured with a split chassis, in two parts, solving most access issues. If you’re still unsure, speak to a member of the team and we will advise on the best option for you.

How reliable is a Target commercial induction range?

Target commercial induction ranges come complete with a 3 years parts and labour manufacturer's warranty on induction components and 10 years guarantee on the range chassis. Target uses additional cooling technologies with induction components ensuring optimum conditions thus minimising technical faults. Unfortunately, hob and wok glass cannot be warranted so check your insurance cover for accidental equipment damage cover protection.

Can the induction hob glass break and what happens if it does?

The 6mm thick Schott Ceran® toughened safety glass, used in Target commercial induction ranges is designed to be extremely durable. It puts up with normal wear and tear of commercial kitchens and everyday cooking without losing any of its stability. However, yes it can be broken under the right conditions, for example if a sharp point or edge is dropped from a height and hits the glass with force then it is likely to crack. If a glass breakage does occur, then just like a car windscreen, it is easily replaced. You should not operate an induction hob with broken glass as this can cause further damage to the electrical components beneath and will void any warranty cover remaining if you continue to use the appliance.

Will having an oven situated underneath an induction hob damage the induction components?

Target commercial induction ranges are designed and manufactured using remote generators, cooling technologies and DualCool® systems to ensure no damage can be caused to induction components by excess heat from built in or modular appliances. If sufficient air-flow and heat dissipation methods aren’t incoporated into a induction suite this can cause major issues with built-in induction components.

What makes an induction plancha griddle better than a standard electric plancha?

With an induction plancha griddle the cooking plate surface is heated with induction technology providing faster heat up times with a consistent temperature across the entire cooking surface. RTCSmp® technology senses real time temperature change down to the degree creating a highly responsive cooking surface with rapid temperature control, much faster than traditional gas or electric heating elements.

Do I need to have special induction pans for my commercial induction hob or can I use my existing pots and pans?

Yes you can use existing pots and pans provided they are magnetic. However, be careful with pans that have previously been used on gas ranges as they may have warped under high temperatures which when used on induction hobs can create heat spots within the pan causing abnormal temperature feedback to safety sensors that protect components mounted under the glass. Some pans will work better than others, for optimum efficiency when using a commercial induction hob it is recommended to use good quality induction ready pans. For more advice on induction compatible cookware CLICK HERE.

Is induction more expensive than gas to run?

Induction is very energy efficient and costs less than gas to run because of automatic pan detection, switching power on only when required, results in little wasted energy costs. Also, because energy is generated directly in the pan it speeds up cooking processes also providing minimal running costs.

What are the potential energy savings I can make if I switch to induction cooking technology?

Typically you can expect to make savings of upto 60% on energy costs by switching to induction from gas. Here is a typical example prepared by Target to support Carbon Trust funding applications to replace gas fired energy inefficient equipment with more energy efficient cooking equipment;

4 burner gas hob 4 x 5.8kW = 23.2kWh x 6.66p = £1.56

4 zone induction hob 4 x 3kW = 12kWh x 13.86p = £1.66 x 0.5 (half the time) = £0.83 x 0.75 (25% saving through auto pan detection) = £0.62

This equates to a financial saving of approximately 60% off from the current gas consumption cost to do the same job with induction cooking equipment.

What on-going maintenance is required with induction?

On-going maintenance is minimal and induction suites typically only require the checking of electrical connections for integrity and checking air filters and cooling fans are kept clean and clear of dust and debris. Regular servicing of applicances will help to maintain optimum health of the products.

Does induction go wrong and what happens if it does?

It is possible for every machine or appliance to go wrong, but induction, in particular heavy duty, is very reliable especially as it has minimal mechanical moving parts that can go wrong. With Target commercial induction ranges, in-built computer systems monitor and manage the thermal health of generators and component parts, with flashing code lights displaying error codes for engineers to fix. Induction hobs are able to protect themselves from major damage as they are designed to cut-out and fail safe if abused or overheated through the use of poor quality pans and/or user error.

Benefits of Induction Cooking

Learn how you can save you money without compromising the quality of your products with Commercial Induction Cooking.

5 REASONS TO CHOOSE INDUCTION

By providing rapid, controllable and precise heat and at the same time as saving energy, the benefits of induction cooking are immense.

Induction hobs have a smooth glass surface on which pots and pans are placed. An induction coil and gererator is located beneath the glass surface and by placing an induction-ready pan on an activated induction hob, a magnetic field is created. This magnetic field heats the pan and the food contained within it. The pan and the food inside will heat up, not the induction hob. When the pan is removed the magnetic field is broken and the hob will automatically stop generating heat and consuming energy.

1. Save Money

Automatic pan detection: energy only used when a pan is on the hob

Pan heated directly: 90% energy efficient compared with 40% efficiency with gas

No waste heat expulsion means cooler working environment and less ventilation requirements

No need for expensive gas safety interlocks - essential in catering kitchens using gas to cook

2. Safe

No hot surfaces: only residual heat generated from the cookware

Child lock facility: no unauthorised access - ideal for use in schools where safety is a key issue

No naked flames or glowing electric elements - helps avoid setting things on fire

Automatic switch off when boil dry detected or pan removed from cooking zone

3. Quick and Easy

Rotary controls: understandable control system

Rapidly heats up pan: no energy is wasted therefore cooking is faster than gas

Controllable instant response: ingredients can be cooked at a precise temperature

4. Clean

Ceran® toughened glass flush with hob makes for a wipe clean surface

Spills do not burn on meaning no lengthy cleaning times

Mobile units can be easily moved to enable access for cleaning behind units

5. Flexible

Suitable for all types of cooking: induction wok hobs ideal for Asian cooking

Extra work surface: when not in use built in induction hobs can be used as a work top

Bespoke combinations to meet your exact specification

About Induction Zones and Coils

induction zone options

Choosing Your Coil Configuration

There are a number of induction zone types available designed to suit the varying cooking styles, techniques and needs of today's chefs. Induction zones vary in size, shape, positioning and power output allowing for different cooking vessel sizes and styles to be used effectively. With Target commercial induction you are not restricted to a single zone type. Each commercial induction range be it standard or bespoke can be configured to meet your exact needs, mix and match to ensure you get a product that is perfectly suited to you.

CIRCULAR ZONES

Best for single pan operation, circular induction zones provide very even cooking temperatures, and are designed to replicate an open top burner on a gas range.

-

Each circular induction zone is intended for single pan operation

Circular induction zones provide even cooking temperatures across the bas of a single pan

To replicate the characteristics of an open top burner on a gas range the circular induction zone is ideal

Each circular zone is individually controlled

RECTANGULAR ZONES

Similar to the square zone, however the rectangular induction zones give two sensors in the space of one if it were a square zone resulting in greater temperature monitoring of multiple smaller pans.

-

Rectangular zones are suitable for single or multiple small pan cooking

Each zone is controlled individually

The individually controlled zones across the cooktop produce similar characteristics of an induction solid top or slide controlled top, however offer more flexibility in temperature control

Rectangular zones provide versatility in temperature control across the cooktop

SQUARE ZONES

Provide a larger surface area for cooking, suitable for a single pan or multiple smaller pans, whilst ensuring even heat distribution, without the creation of hot spots.

-

Square induction zones are the most versatile type of zone

For independent single pan use or combined to create extra large heat zones for multiple pan or large stock pot use, the square induction zone is ideal

Each square zone is controlled individually providing maximum flexibility in temperature control

Combining multiple square zones produce similar characteristics to a hot plate creating an induction solid top or slide controlled top

WOK FORMED ZONES

The wok formed zones allow for those who prefer to use a round wok pan instead of a flat based wok pan to cook efficiently using induction as an alternative to the traditional gas wok range .

Wok zones are fitted with a stainless steel edging plate for extra protection for the Ceran® toughened safety glass.

-

For use with round base wok pans as used in traditional oriental cooking

Recessed glass formed wok zones are fitted with an additional stainless steel edging plate for added protection to the glass

INDUCTION SOLID TOP - SLIDE CONTROL ZONES

The induction solid top slide control zones offer a cooktop surface with pre-programmed gradient heat zones, temperature controlled by a single rotary controller. Perfect if you want to go from a rolling boil to simmer by simply sliding a cooking vessel across the cooktop surface. Choose from a linear or square configuration. Each zone is pre-programmed to varying maximum power outputs and graded to your power requirements.

Induction solid top slide control zones can be used for multiple small pan cooking or larger single pan cooking, replicating the traditional hot plate or gas solid top stove. Once the power is on, simply move the cooking vessel around the cooktop surface for varying graduated temperatures.

-

The induction solid top / slide controlled top consists of square and rectangular induction coils installed under the cooktop.

These induction zones are individually programmed at different power ratings.

The induction solid top / slide controlled top is controlled by a single temperature controller which regulates a pre-programmed power gradient.

The Induction solid top / slide controlled top is suitable for single or multiple pan cooking.

The slide controlled top creates the effect of a hot plate or induction solid top where typically heat graduates from one end to the other.

Once the induction solid top is turned on you can vary the temperature within the pan by moving it across the cooktop.

Can't find what you're looking for? CALL NOW 01452 410 447

Approved Electrician

We are looking for a confident Approved Electrician to join our expanding team to support the products we manufacture and supply. If you have recent experience in electrical wiring and assembly and would like to have a critical role in the support and development of existing and new products within the food service equipment industry, then we want to hear from you!

PRODUCTION / SERVICE / MAINTENANCE

As a growing British manufacturer within the food service industry we at Target Catering Equipment are looking for a confident Approved Electrician with commercial/industrial experience to join our expanding team to support the products we manufacture and supply. If you have recent experience in electrical wiring and assembly and would like to have a critical role in the support and development of existing and new products within the food service equipment industry, then we want to hear from you!

The role will be predominantly electrical assembly and maintenance but will include general assembly. There is also an opportunity to do metal work if this appeals. The role will involve workshop and on-site working.

Permanent, Full Time

Location - Gloucester, Gloucestershire

Salary - Competitive (negotiable depending on experience)

Overview -

KEY TASKS & RESPONSIBILITIES

Manufactured equipment and control panel assembly and electrical wiring

New installation works - complete kitchen installations

Small work electrical services installation

Fault finding

Planned preventative maintenance and reactive service calls for commercial catering equipment

Maintenance of plant, machinery and production equipment

PAT testing

Record keeping

PERSONAL SKILLS & EXPERIENCE

Minimum 1 year experience in electrical maintenance - commercial / industrial

Qualified or experience in electrical fault finding

Experience of working with single phase and three phase electrics

18th Edition - Electrical certification

Good communication skills

Self motivated

Flexible team player

Willing to learn and be multi-skilled within workshop environment

Clean driving license and passport

Advantageous but not a necessity;

Experience in doing site installations

Experience in repairing and servicing electrical catering equipment

Fabrication experience working with thin sheet metal (stainless steel)

Electrical test and inspect certification

Forklift driving licence

Basic plumbing knowledge

BENEFITS

Competitive salary + Overtime (negotiable depending on experience)

Monday - Friday days based

22 days annual holiday + bank holidays

Company pension

Life insurance

Manufacturer specific training provided, as required

Provision of a van and fuel card

Full uniform provided

On-site parking

To apply for this role please email your CV and covering letter to charlotte@targetcatering.co.uk Subject: Approved Electrician

Junior Design Engineer

We are looking for a Junior Design Engineer to join our expanding team. If you have recently graduated with a Design Engineer or similar qualification or have product design experience, with a basic understanding of using thin sheet metal and electro-mechanical components and would like to begin your career and have a supporting design role in the development of existing and new products within the foodservice equipment industry, then we want to hear from you!

MANUFACTURING / PRODUCTION

As a growing British manufacturer within the food service industry we at Target Catering Equipment are looking for a Junior Design Engineer to join our expanding team. If you have recently graduated with a Design Engineer or similar qualification or have product design experience, with a basic understanding of using thin sheet metal and electro-mechanical components and would like to begin your career and have a supporting design role in the development of existing and new products within the food service equipment industry, then we want to hear from you!

Permanent, Full Time / Permanent, Part Time

Location: Gloucester (Office Based)

Salary - Competitive (Dependant on experience)

THE ROLE - KEY TASKS & RESPONSIBILITIES

Customer liaison - Recieve design briefs, understanding customer requirements and specifications

Generation of product models to suit customer design briefs using 2D & 3D CAD software

Support Senior Design Engineers with new and existing product research and development

Production of product design and development drawings/sketches

Transformation of product design sketches into 2D/3D models, working part, manufacture and assembly drawings

Reverse engineer existing components to produce accurate reproduction in 2D/3D CAD

Document and drawing amendment control & product improvement implementation

Preparation of product specification sheets, bills of materials/components and all associated technical documentation/manuals

To detail and maintain manufacturing sequences, documenting times and standardizing manufacturing processes

Liaising with engineering & production teams to ensure timely execution of all tasks, both those of new and existing products and components

Liaising with Management teams to prepare and maintain detailed costings of fabrication and standard end user product price lists

Collaboration with both internal staff, external associates and customers over best practices

Internal and external basic technical support

Preparation and Implementation of our quality control and inspection documents and procedures

SKILLS & EXPERIENCE

Qualified to degree level in either Product Design, Design Engineering or Mechanical Engineering or similar field

A minimum of 1 years working experience in a relative field

A competent user of AutoCAD & Inventor - Minimum 1 year working experience is essential

Proficient with MS Office, particularly Word, Excel and PowerPoint

Ability to read and understand engineering drawings

Ability to visualise products and components from flat form to finish

Practical understanding of solid and surfacing techniques to create robust models

Knowledge of design to manufacture, forming processes, manufacturing techniques, complex mechanisms and material properties, capabilities and limitations, particularly using thin sheet metal and electro-mechanical systems

Ability to generate 2D manufacturing drawings with practical working tolerances and key inspection dimensions

Ability to communicate well with management and other staff members

Excellent presentation skills with a keen eye for details

Ability to work well under pressure

Systematic/methodical approach to work, along with the ability to balance workloads for each area

Good team player with the ability to work under your own initiative

DESIRED SKILLS & EXPERIENCE

Customer handling and sales experience

Understanding and knowledge of commercial kitchens and food service equipment

CFSP qualified

Ability to prepare complete commercial kitchen layouts

To apply for this role please email your CV and covering letter to charlotte@targetcatering.co.uk Subject: Junior Design Engineer

Commercial Kitchen Design Guidelines

The aim of planning a commercial kitchen layout is to achieve a work area which creates maximum efficiency, keeping wastage of labour, energy and materials to a minimum, whilst also being safe for staff and customers, complying with all commercial kitchen design regulations.

Whether a large or small catering kitchen for a restaurant, hotel or pub, the following basic commercial kitchen requirements apply and should be considered when designing your commercial kitchen equipment layout:

DELIVERIES

Delivery vehicles should have good access to your premises and where possible a direct route to the catering area.

A dedicated goods in point is preferred where deliveries can be received, eliminating the need for delivery personnel to enter food prep zones.

Allow adequate space for storage of dry, chilled and frozen goods to ensure efficient sorting of goods in.

STORAGE

Ideally separated/dedicated refrigeration storage for meat, dairy, fish and fresh vegetable products.

Dry goods stores should have adequate ventilation to avoid damp conditions which can affect dried produce.

Separate COSHH lockable storage should be available for storage of cleaning chemicals and hazardous products.

FOOD PREP

Consideration should be given to segregating raw food from prepared food although this may not be possible when space is limited.

Position prep areas between bulk storage and main cookline.

Ensure adequate prep sinks, hand wash sinks and pot wash sinks are easily accessible.

COOKING EQUIPMENT

When choosing cooking equipment always consider your type of menu.

Where possible, the installation of energy efficient cooking equipment should be considered. By installing induction cooking equipment, combination ovens and energy efficient grills not only will you save on energy costs but this will also speed up the delivery of dishes to customers and cut down the amount of time spent on cleaning and maintenance of cooking equipment reducing ongoing operational costs.

When designing the layout of a professional kitchen safety and workflow should be thought about carefully.

Make sure that the flow through the kitchen suits your style of service. Fast cook equipment such as fryers, griddles and salamanders should be positioned nearest to the service point and bulk cooking equipment such as convection ovens, combi ovens, bratt and boiling pans further away.

MECHANICAL AND ELECTRICAL INSTALLATIONS

Consideration should be given to the type of M&E services available. In remote areas a gas connection is not always possible and all electric kitchens will need to be considered. Target Catering Equipment’s induction hobs and cooking suites offer an ideal alternative to traditional gas cooking ranges.

Always check the incoming electrical supply has the capacity required for the equipment specified, a three-phase electrical supply may need to be installed.

An important part of a well-designed kitchen is the service spine or service manifold. Within this structure most, if not all of the associated services can be located for equipment situated around it. This is usually installed as an island unit and incorporated into the design of the ventilation system.

VENTILATION SYSTEMS

Commercial kitchen ventilation is a key part to your catering kitchen, where gas cooking equipment is specified there are stringent rules and regulations, and gas safety interlock systems need to be installed.

You can achieve a cheaper ventilation system solution, which does not require expensive gas safety interlocks, by installing an all-electric kitchen including induction hobs and commercial induction ranges which Target manufacture to order.

FOOD SERVICE AREA

Adequate space for holding hot and cold food prior to service should be alocated. The provision of heated gantries and hot hold bins will help food to stay hot and a correctly designed food service area will enable smooth transition of dishes from the kitchen to the dining area or service point.

DISHWASHER AREA

The dishwashing area is of paramount importance to the successful running of a catering business. Consideration should be taken to providing enough space for the storage of clean items as well as disposal of rubbish and waste food. Target Catering Equipment manufacture dishwasher tables and complete dishwashing systems to suit exact requirements.

A condensate canopy may need to be installed in order to capture steam produced during the dishwashing procedure, Target manufacture stainless steel condensate canopies to suit all requirements.

Gaining the Right Consents and Getting Through Planning

Catering Kitchen Planning - Technical Specifications

Setting up a foodservice business in a new premises can often require planning permission for ‘Change of Use’. Anyone can submit a planning application, however you may need specialist information to assist a successful application with minimal conditions for a foodservice business.

Target Catering Equipment can produce detailed technical specifications for submission to local authorities requesting information on ventilation systems, odour and noise control measures, as well as generating building floor plans, sections and external elevations showing the proposed technical details.

Compliance with Planning and Environmental conditions can save you heartache and a lot of money should you choose not to follow specialist advice. Retrospective applications and non-compliance will be costly, so make sure you get it right first time to save time and money.

Planning Permissions and Licenses

Questions you will need to ask prior to embarking on your new build kitchen design:

Do you need to apply for planning consent?

Is your development in a conservation area or listed building?

Do you need to apply for building regulations compliance for alterations?

Do planning conditions need to be discharged prior to installation of a kitchen ventilation system?

Do you need to apply for a license to operate or a change of use: i.e. from commercial property A1 Retail to A3 Restaurant or A5 Hot Food Takeaway?

Target's 2024 Project of the Year: A Star Achievement

By David Pedrette - Managing Director, Target Catering Equipment

Coventry City Football Club’s Training Ground Players Kitchen

“It’s always hard to choose just one, but, a project that made me most proud this year has to be the design, supply, and fit-out of Coventry City Football Club's new training ground players kitchen at Sky Blue Lodge. Our clients required an ultra-fast turnaround, and the Target team came together from start to finish, delivering an exceptional result.”

Crafting a Modern and Functional Kitchen

Target designed an all-electric commercial kitchen tailored to fit the newly refurbished training ground facility. The focus was to provide professional footballers and staff with high-end, healthy cuisine while avoiding the use of deep-fat fryers.

The project also involved the design and manufacture of a specialist free-standing commercial kitchen ventilation system that incorporated air supply and extraction. This included an island extractor for front-of-house open kitchen use in a low-ceiling dining area. The system featured an electrical service manifold with switchgear, powered by a Schneider distribution board with RCD and surge protection devices to ensure safety for both people and equipment. The kitchen showcased cutting-edge energy-saving technologies, including sophisticated Target commercial induction range cookers, Adande refrigeration and the advanced Hounö Invoq hybrid steam combination ovens.

Efficient Dishwashing and Flexible Storage Solutions

The project included a bespoke dishwashing system featuring a state-of-the-art Meiko passthrough dishwasher with steam condensate heat recovery system. Alongside this, we installed Target bespoke fabricated items including bespoke dishwash tabling with sinks, creating an efficient pot-wash and dishwashing area. This also incorporated a dedicated bespoke Target waste station for tray-clearing, waste-sorting, and recycling for use front of house by the players.

For food storage, Adande drawer refrigeration was chosen for its ability to switch seamlessly between fridge and freezer modes. This adaptability provided ultimate flexibility to meet changing demands.

Innovative Front-of-House Cooking Station

Reconfiguring existing front counters allowed us to create a front-of-house cooking station for cook-to-order items. This unique setup would enhance the service offerings that could be delivered by the caterers at Sky Blue Lodge, delivering a standout experience for their customers.

Overcoming Challenges with Smart Solutions

During the project, unexpected structural support steelwork impacted the original design. However, Target’s fabrication team expertly resolved these issues with smart thinking and modifications. Their proactive approach ensured there were no delays, allowing the project to be completed on time and within budget.

To ensure a seamless handover, full user training was provided by equipment manufacturers on-site. The chefs were thrilled with their new kitchen, designed to meet their professional needs.

Team Excellence in Project Management

The project was expertly managed by Target’s Charlotte Pedrette, making it one of the smoothest operations to date. Special equipment design was led in-house by head of product design Nicola Pedrette and her team, who ensured every detail was executed to perfection.

Looking Ahead…

With this prestigious project successfully completed, we look forward to the next year and the next opportunity to design, supply, and fit out a unique project that will once again make Target proud.

Ardor St. Ives - The Josper

We interviewed head chef and owner Dorian Janmaat about his experience with the Josper Charcoal oven and how it has benefited his restaurant. At Target Catering Equipment, we pride ourselves on delivering high-quality commercial kitchen solutions, and we're thrilled to be a trusted supplier of the renowned Josper charcoal oven. This exceptional oven, known for its unique combination of grill and oven capabilities, allows chefs to bring intense smoky Flavors to their dishes, adding a distinct edge to any culinary experience. In this interview, We spoke with the team at Ardor St. Ives a Mediterranean-inspired restaurant about how the Josper has impacted their service, transformed their menu, and what it was like working with Target to bring this unique element to their kitchen.

Q1: What inspired you to choose Josper for Ardor?

The Josper was a perfect match for us because it’s a high-quality, well-crafted appliance that fits the Mediterranean feel of our restaurant. Since we specialize in seafood and red meats, the Josper’s versatility and robust grilling capabilities really enhance our cooking style. It brings a beautiful, smoky flavor to our dishes and creates a strong identity for the restaurant. In many ways, it’s the heart of our kitchen, tying together the atmosphere and personality we want Ardor to have.

Q2: What made you choose Target as a supplier for the Josper?

We actually heard about Target through word of mouth and were told they’re one of the best suppliers for Josper ovens. The whole process was a pleasure from start to finish. Target provided excellent communication, support, and a thorough understanding of our needs. It made the decision to work with them very easy.

Q3: As a chef, if you could recommend one ‘must-have’ Josper dish from Ardor, what would it be and why?

Definitely the on-the-bone Duroc pork tomahawk with garlic butter. It’s a special dish created by our chefs and is unique to Ardor. It requires a longer preparation and cooking process, but it’s worth it. The Josper’s intense heat and smoky flavor make this dish incredibly tender and flavorful. It’s a standout on the menu and captures the kind of dining experience we want to offer.

Q4: What do you feel the Josper oven brings to the restaurant?

It really adds a ‘wow’ factor. Since we have an open kitchen, guests can watch the chefs using the Josper, which makes the whole dining experience more immersive and enjoyable. The aroma, the sound of the fire, the presentation—it’s all part of the experience. The Josper brings a unique atmosphere that we couldn’t achieve with any other oven.

Q5: How have your first two months been since opening, and what are you most looking forward to as Ardor grows?

The first two months have been fantastic. We’ve seen a great mix of locals and tourists, and there’s been a strong, positive energy in the restaurant. Our team is in high spirits, and as we look ahead, we’re excited to develop our menu further, experimenting with the Josper to bring out even more of its unique qualities.

Q6: Overall, how would you rate the Josper oven?

It’s a 10/10 for us. It’s low-maintenance, easy to clean, and efficient with charcoal use. The team found it easy to operate, and it has seamlessly integrated into our kitchen setup. Plus, the flavor it brings to the food has helped make Ardor stand out as a dining destination. It’s everything we’d hoped for and more.

Q7: Which Josper dish has been the most popular among your customers?

The pork ribs have definitely become a favorite! We prepare them with a Spanish artisan sauce from Mevalco, which adds a unique touch. They’re slow-roasted first, chilled, and then finished off in the Josper. It’s a method that has been a real crowd-pleaser.

Q8: Since opening, what would you say has been your biggest achievement?

Receiving such great reviews and feedback from customers and other professionals in the industry has been amazing. We’re becoming known as a must-visit spot in the area, which feels like an incredible achievement so early on. Our goal now is to keep growing and hopefully gain recognition as a destination restaurant throughout the UK.

In our interview with the team at Ardor St. Ives, they shared how the Josper charcoal oven has transformed their kitchen, enhancing the flavors of their Mediterranean-inspired seafood and meats while creating an unforgettable dining experience for guests.

If you'd like to learn more about the Josper charcoal oven and its capabilities, reach out to Target Catering Equipment at 01452 410 447 or enquiries@targetcatering.co.uk.

Our team is here to answer any questions and can even arrange a demo, allowing you to experience the Josper’s impact firsthand before making a purchase

“I’ve known Target as a top supplier of Josper ovens, and they come highly recommended.

Working with Charlotte and David has been a fantastic experience, their customer service is both professional and personable. Communication has been great, and it’s truly been a pleasure to work with you.”

5 Reasons Why a Restaurant Should Implement Planned Preventative Maintenance (PPM) for Induction Cooking Suites:

Enhanced Precision and Consistency in Cooking

Induction cooktops are prized for their precise and even heat distribution, which allows chefs to maintain consistent cooking temperatures. Regular maintenance ensures sensors and controls function correctly, preserving these precision benefits. Properly maintained equipment helps deliver consistently high-quality dishes, which is crucial for customer satisfaction and brand reputation.

Prevention of Downtime and Service Disruptions

Induction hobs rely on sophisticated electronics and magnetic coils, which can be sensitive to wear and dust accumulation. PPM helps keep these components in top shape, reducing the likelihood of sudden malfunctions. This proactive approach minimizes downtime during busy service hours, so chefs don’t lose valuable cooking stations during peak times.

Extended Equipment Lifespan and Cost Savings

Induction equipment can be a significant investment, and replacing parts like generators or magnetic coils can be costly. Routine maintenance keeps the equipment functioning optimally, prolonging its life and delaying the need for replacements. Preventative measures are typically less costly than emergency repairs or full replacements, helping restaurants save in the long run.

Improved Energy Efficiency and Lower Utility Costs

Induction cooking is already energy-efficient, but neglected equipment can develop faults that lead to inefficiencies, such as power surges or reduced heat transfer efficiency. Regular inspections and cleaning allow the equipment to maintain its high energy efficiency, translating into lower electricity costs and a reduced environmental footprint for the restaurant.

Better Staff and Customer Experience

Equipment breakdowns can create stressful situations for staff and lead to longer wait times for customers. PPM keeps equipment running smoothly, allowing staff to focus on service rather than dealing with maintenance issues. A consistently well-operating restaurant creates a more enjoyable environment for both staff and customers, enhancing overall satisfaction and loyalty.

In summary, implementing PPM for induction cooking equipment helps maintain performance, prolongs its lifespan, enhances energy efficiency and promotes a safe and smooth-running kitchen environment. These benefits collectively support better service quality and operational efficiency for the restaurant.

Target Supporting British Farming

Target have been backing and supporting British Farmers for many years as they diversify and want to achieve their own added value to the crops they grow and livestock they breed. This can take many forms and Target have something for everyone including years of experience to give good balanced advice as only another manufacturer can give to another producer.

Target have helped Farms for City Children in farthest West Wales provide the valuable rural life experience of living and working on a farm to spread the word about where food comes from and how it is produced when so many think it comes from a shop window at the local drive through take away.

Farmers have always struggled to achieve sustainable reward to cover production costs in a high welfare and highly regulated industry controlled by large supermarket buying chains that cannot cope or help the smaller farmer that the larger farmers feed off.

Its understandable that you must innovate as a farmer to get the return on investment to make it all worthwhile.

Farm-Ed in the Cotswolds came to Target to help design their new kitchen at their regenerative farming centre of excellence which showcases an amazing conference and event facility just down the road from Jeremy Clarkson’s Diddley squat farm of TV fame.

Target have also helped Mr Clarkson’s Diddley Squat Farm contract caterers for his farming enterprises develop their production kitchen near Chipping Norton to process what Mr Clarkson produces on his farm in West Oxfordshire.

Down in Somerset at Frogmary Green Farm Target helped convert a cooking skills teaching kitchen to service the amazing Farm and Field Café that enjoyed massive expansion and success during covid and has gone on to provide a wedding event space and diverse work shop space on the former chicken farm that now produces Bio Methane on a massive scale.

Up in Herefordshire Target helped Newton Court Farm start the Chapel of Apple cider farm restaurant and event space that also offers cider making tours as it produces cider for the River Cottage farmer/restauranteur/journalist down in Dorset Hugh Fearnley Whittingstall.

Locally in Gloucestershire we are very luck to have native pigs and cattle that carry the Gloucester title so when farmer Clifford Freeman heritage breeder of Gloucestershire cattle wanted help at his hotel on the Scilly Isles Target were there to help as they have also done up in the highlands and Islands of Scotland.

There is no end to what farmers can do and use their land for to develop their businesses. Target will always be here for them as a centre of excellence where they can come and visit talk to us see and use equipment that they may wish to consider adding value to food cooked using the very latest most energy efficient and special equipment available.

Check out the Westmorland Farmers Tebay Motorway Services and Reghed Centre in Cumbria as well as Gloucester Motorway Services on the M5 to see what farmers can do with the right attitude and a little help from Target Catering Equipment supporting British Farmers.

Unlock the Power of Smart Energy Management with KI Tech

KI Tech

Do you have an old gas kitchen and want to upgrade to an energy efficient all electric kitchen but you have no idea if you have enough power and electrical capacity to enjoy the latest equipment available on the market along with electrical vehicle charging points for your guests.

Your electrical contractor is unsure as you have no means to accurately monitor what you are currently using or what your peak loads are and how close to the wire you are sailing away from blowing your main incoming fused protection cut offs.

Transform your kitchen and business operations effortlessly by renting a state-of-the-art KI Tech monitoring system. Get all the insights you need to make informed decisions about your energy usage and take control of your future costs.

Our Services

Monitoring & measuring

It’s a no brainer as if you do not monitor it, you cannot measure it and if you cannot measure it, you cannot manage it or make decisions.

Investing in your future

Save yourself thousand in the future and improve your business making it more sustainable and minimising your carbon footprint reducing your energy consumption by optimising its use.

Talk to a Target specialist

If you want to know more about this latest technology speak to a Target specialist today and receive an introduction pack so you know what to do next!

What makes JOSPER elite from the rest?

Others who try to mimic Josper often find that their products do not achieve the desired controlled high temperature for grilling, resulting in a lower working temperature range compared to Josper. This reflects in poorer grilling performance.

Josper uses high-quality refractory cast steels, making it faster, more powerful, and more agile when grilling, with consistent performance throughout the entire service. Josper oper

The continuous action of fire and heat exposure causes significant deterioration, a factor Josper has considered in its philosophy, aiming to build strong, reliable, and durable ovens. Many customers and friends have enjoyed their Josper ovens for over 30 years.

Competitors have created fabricated steel doors that do not withstand the expansion, contraction, and continuous extreme heat the grill is exposed to, causing distortion, cracks, and breakages.

The Josper door, a basic component of the system, isolates and retains heat inside. Chefs love it! Designed and built with refractory cast steel, its robustness guarantees the best performance under high temperatures and handles the expansion caused by heat. This is one of the advantages of Josper ovens and a key point for their excellent performance.

Air Entry:

Others who try to replicate Josper use a simple drawer for air entry and ash collection; this drawer doesn’t close hermetically, allowing air to enter and turning the oven into a machine with poor control. This leads to high charcoal consumption. When oxygen enters, flames appear inside, causing distortion and faults in closing the door properly.

Since its inception in 1969, Josper has designed and produced ovens with a hopper-shaped lower part, allowing air to enter more homogeneously and naturally. To increase operational safety, there is a cast register that controls the air entry, ensuring hermetic closure and regulating charcoal burn.

The Result:

• An easy-to-control oven

• Higher control of the embers

• Extinguishes 95% of the flame

• Huge charcoal savings

IMPORTANT! The brand quality is shown over time. Josper has been producing ovens for over 50 years, serving more than 40,000 customers (100% made in Spain), and is present in more than 123 countries across five continents. Josper provides technical and chef consultancy services worldwide.

All quality certificates of Josper products are based on tests conducted in prestigious, solvent, and independent laboratories, unlike those who try to copy the design.

Difference between Josper and the latest competitor equipment released on the market

The appearance is the only feature that has been mimicked by others who have tried it. The intention is to create confusion to the client, tying to convince them of purchasing something similar to a JOSPER

10 Factors Set To Impact Operators in 2024

Rising Costs - with rising operating costs and a cost of living crisis both continuing to impact the sector and the bottom line for operators, one of the key challenges to overcome in 2024 remains managing costs and maximising revenues. Lee Brooks, head of food at McMullen’s pub group, said: “I would say one of the biggest challenges we are facing are prices/ costs – food, utilities, wages etc., which have continued to rise for some time and show little signs of slowing. Unfortunately, these costs have to be passed on as we simply can’t afford to absorb them”.

Climate Change – Climate change will continue to have an impact on menus and pricing, according to seamus O’Donnell, culinary director at the Alchemist. He commented: “Crop yields are smaller and size of harvested product is drastically reduced, as well as the results of flooding leading to loss of crops or failure to harvest.”

Staffing - As pressure continues the mount for operators due to skills shortages and other recruitment challenges, this is likely to remain one of the major concerns for businesses this year. Stuart Duff, corporate chef for the UK and Ireland at Hilton, said: “The biggest issue is recruiting quality highly-trained staff into the business at mid-kitchen level – demi CDP and CDPs. I feel this is an industry-wide issue. The national living wage increasing and mid-Skilled chefs who have year’s experience. The gap is getting smaller for the national living wage due to salary structures, thus driving people out of the business of hospitality into higher paid and easier, less skilled roles.”

Energy Efficiency – Sky-high energy costs have been blighting the industry in recent times, with operators keen to get some respite from unsavoury bills, and regulator Ofgem finally showing some signs of support for businesses facing unfair charges from suppliers. Stuart Duff from Hilton said: “I am working on an exciting project of designing the banqueting kitchen for the future. I am looking at the best equipment on the market and labour saving equipment, such as self-cleaning Bratt pans, plated regen ovens, and adequate storage for capacity, creating a linear workflow from preparation to service using the most advanced equipment available and putting this into action in one of our Hilton hotels.”

Menu Options and Design – Menu design and presentation can be a key method to draw in the customer and keep them interested. Dean Wilson Hartles, director of food and drinks development at the Restaurant Group, said: “Use complex descriptions for every item on the menu, but sparingly. Longer, more detailed menu descriptions of dishes can increase sales up to 20%. Doing so gives more information about a dish, making it sound more impressive, and tends to draw attention from the price. However, don’t use complex descriptions for every item on the menu. For some simpler dishes, such as sides, this isn’t necessary. Having thorough descriptions for a select few makes these dishes seem more impressive and so they stand out from other menu items.” He noted that once a menu has been engineered, operators should be constantly reviewing it to determine what is selling well and why some dishes may be under performing.

Digital Growth – In an opinion piece for FEJ focusing on the importance of PizzaExpress’ recent digital transformation, Arslan Sharif, digital and loyalty director, wrote: “whilst developing the PizzaExpress club app has been a key focus for us, our digital transformation has extended to other areas too. For example, in 2022 we simplified our collection ordering journey and made it easier to order via the website for a pre-determined pick up time; more recently in 2023, we introduced PizzaExpress Delivers, whereby customers can order directly from our website for a delivery to enjoy wherever they are.”

Food Waste – Paul Bate, NEC Group food and beverage director, said that implementing advanced inventory management systems can help optimise food margins and reduce waste, while automation technologies can drive labour efficiencies to counter the impact of labour or skills shortages. “Utilising smart kitchen appliances and data analytics can enhance operational efficiency and meet evolving consumer expectations. We were the first catering company to introduce an AI waste management tool (Winnow) to our operations, which has already driven behavioral change in our kitchens though better understanding of our waste streams (product, specification, and process)”. The company said since the technology was introduced at the ICC venue, food waste on site has been reduced by a third, while more than 20 tonnes of food has been saved – the equivalent of over 51,000 meals.

Sustainability – This is one of the hottest industry topics that will continue to be addressed this year. Over at Compass Group, Mr Holmes, said that in response to the call for sustainability where often clients share the same net zero goals as the firm’s, the group is already reshaping practices and aligning with eco-friendly approaches, from ingredient sourcing to waste reduction. He added: “As challenges mount, technological solutions offer a way forward. The biggest issue affecting us at the moment is instability with utilities – both for us and for our guests. It is our responsibility to deliver value against a backdrop of these cost of living challenges which are impacting us all. We are looking at various new initiatives including equipment, software, and waste management, to support us with our key objective to achieve net zero in 2030.”

AI/Automation – Embracing innovations like AI-driven menu optimisation and customer engagement tools will be pivotal for the NEC Group’s catering growth over the next year, Mr. Bate said. He commented: “Our company is committed to focusing on sustainability and efficiency in kitchen operations – driving our waste and efficiency savings with Winnow even further” Arslan Sharif from Pizza Express, added: “Overall, I would say that the future of digital loyalty schemes in the UK dining sector looks strong, especially with the leaps in the advancement of AI technology in recent months, which could have notable implications on delighting customers through even more personalised experiences”.

Kitchen Screens – Kitchen screens are becoming a common trend to help streamline operations, according to Mr. Brooks at McMullen’s and Mr. O’Donnel at the Alchemist. Mr Brooks said: “Having the right piece of kit for the right job is so important, and our biggest use of technology over the last 18 months to two years has been from kitchen screens. The screens take the pressure off the kitchen and allow chefs to focus on the dishes that section needs to work on. It removes the noise of the old kitchen printer which has been known to trigger, removes the risk of a lost ticket, and everyone can see what they need including front of house”.

To Vent or Be Ventless

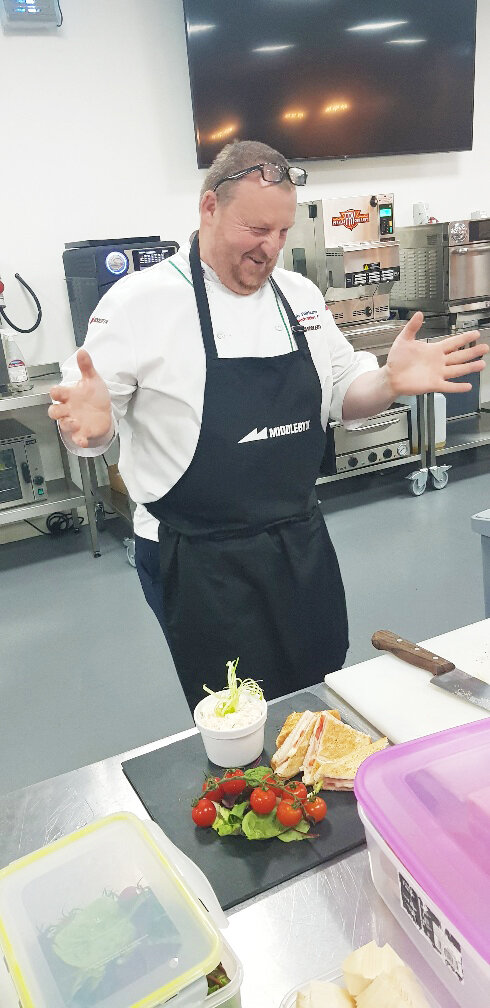

To vent or be ventless, that was the question to be answered at Middleby UK Centre of Innovation and Excellence by the Houno Blodgett Hoodini combi oven. Brought to the UK market by Lincat, part of the Middleby Corporation, the first ventless Hoodini unit to arrive in the UK was sold by Target Catering Equipment to the Agroecology Farm Ed centre, based in the Cotswolds.

The recent official launch to introduce the “ventless” concept demonstrated how chefs can utilise this new technology, taking the pain and stress away from traditional cooklines, and developing menus and concepts optimised by equipment choice.

Rob Fairhurst, Middleby UK’s development chef, showed how easy cooking using the Hoodini combi oven was and with perfect mise en place preparation, how performance could be elevated. By having equipment programmed to specifically cook each individual item on the menu enables anyone to cook to perfection.

The Hoodini Combi is the first truly ventless combination oven with its Blodgett designed and fitted Hoodini recirculating hood with catalytic converter air cleaning exhaust technology. Delivering clean cool exhaust air from the oven at just 37°C, which is equal to healthy standard body temperature.

Now you can not only re-heat pre-cooked food with ventless equipment, but you can also cook from scratch, a breakthrough in the catering equipment sector. Which means fast, quality foodservice can be achieved without the need for expensive ducted kitchen ventilation systems, with high rise external ductwork being a thing of the past.

The Hoodini opens up many more sites for use by the food industry which had previously required ducting, making them unsuitable due to planning conditions and constraints. As if by magic the Hoodini ventless combi oven along with ventless Perfect Fry, TurboChef, Sota and Fire pizza ovens and double batch impingement ovens enable you to get over this hurdle.

If this all sounds double Dutch to you then you need to attend the next ventless demo to see for yourself. These demos can be attended at the Middleby UK Centre of Innovation and Excellence or at one of the Middleby UK dealers demo sites like Target Catering Equipment of Gloucester.

View upcoming events >> https://www.targetcatering.co.uk/live-cooking

“Kitchens are being changed with chefs learning new tricks, make sure you don’t get left behind and try something new and different you cannot fail to like it! We certainly did and so do our customers.” said David Pedrette MD and Technical Design Consultant at Target Catering Equipment.

For more information on Ventless Equipment & Hoodini Combi Ovens Click Here.

New British Standard Gas Regulations Allow Condemned Kitchens to Re-Open

Image: commercial kitchen with gas fired cookine

Covid-19 has caused a lot of chaos and as a result overshadowed an important development within the foodservice industry. The release of BS 6173:2020 - the latest update of the British Standards Gas Safety Installation and Use Regulations for gas-fired commercial catering appliances was published at the height of lockdown in March of this year (2020).

The review and renewal has been made as since the release of the British Standards Gas Safety Installation and Use Regulations in 2009 it has been recognised that some establishments have been condemned and closed unnecessarily due to equipment failing tests that were not themselves accurate.

Many landlords and foodservice businesses experiencing difficult times may feel the benefit of the new regulations as some kitchens that have previously had to close due to interpretation of the former BS 6173:2009 standards and application of them, implying that kitchens were unsafe and air quality poor or at risk, may now be able to re-open by implementing methodology within BS 6173:2020, due to improved accuracy of newly cited testing procedures.

“The new regulations make compliance easier especially if you have gas fired kitchen appliances with an extraction system which incorporates variable speed control fans for the variable ventilation needs of the kitchen. Complete ventilation systems now may not need completely upgrading, providing that air quality can be risk assessed and proven to be safe by monitoring safe levels of CO2 carbon dioxide and CO carbon monoxide within the kitchen environment. Therefore, also providing financial savings for catering establishments all over the UK.” Comments David Pedrette, Managing Director and Commercial Kitchen Design Consultant of Target Catering Equipment.

What is BS 6173:2020 about?

This British Standard covers the safe installation, servicing and maintenance of new and previously-used gas fired commercial catering appliances that burn 2nd or 3rd family gases (i.e. natural gas and LPG respectively).

BS 6173:2020 applies to catering equipment such as commercial cookers, fish and chip frying ranges, fryers, ovens café boilers and urns, bain-marie units, tandoori ovens, kebab grill and barbecues.

Pedrette adds, “Here at Target we believe gas in commercial kitchens is still an issue and all electric, energy efficient kitchens are the way forward for users and operators to save money and make for a better working environment. With electric equipment you can remove the issue of harmful by-products of combustion out of the kitchen, but with gas, a naked flame, there is always going to be a source or fire which comes with serious risks, not to mention the potential for explosions associated with faulty gas equipment.”

So, for those still battling on with gas appliances, ventilation requirement risk assessments have eased but for those wanting to enjoy the full benefit of modern cooking technology, the future really is renewable resource, electric powered equipment. The gas dinosaurs will eventually die out but will live to fight another day coming out of Covid-19 with the latest BS 6173:2020 - British Standard Gas Safety Installation and Use Regulations of 2020.

For more information and advice on the latest BS 6173:2020 regulation and compliant commercial kitchen ventilation call Target on 01452 410 447 or Email here.

The Community Comeback

After almost a month since the UK Government told the British public to avoid pubs and restaurants, many businesses across the country are still in a quandary about where things are going and what the future will hold for their business.

However, some things are clear, people are travelling less and are finding it more and more difficult to get hole of essential supplies through the larger supermarkets.

Local communities are joining forces and transforming their local facilities such as pubs and post offices into thriving central community hubs offering an alternative to supermarket shopping.

Public houses a common sight in many of the UK’s towns and villages have been temporarily closed as requested by the UK government in order to help fight against COVID-19. However, business owners are planning for the future and re-evaluating how and what they can deliver to their local community in order to not become a victim to this virus and come back stronger once the storm has settled.

“It is often the case that many pubs have close links with an array of local farmers, producers and suppliers, along with kitchen facilities with the ability to transform ingredients into a variety of products, as well as meals for takeaway consumption. It therefore makes sense for these sites to diversify and extend their current offerings to their supportive local communities.” Says Nicola Pedrette, Design Consultant at Target Catering Equipment.

Already recognising this are larger pub groups such as Punch Pubs & Co. who have set-up the “Pub Shop” initiative, teaming up with food supplier Brakes to deliver essential groceries to local communities.

Target Catering Equipment’s design consultants have been working closely with a number of independently owned pubs and pub groups to help do just this. With local public houses being central in many communities makes for an ideal location for a central community hub; a public house come local store, delicatessen and/or takeaway.

With carefully thought-out layout designs local communities and businesses can once again begin to thrive in these somewhat unprecedented and uncertain times.

If you’re planning for the future and are interested in expanding your offering take the first step and speak to a Target design consultant for free professional advice about how you can transform and expand your business.

Image: Punch Pubs & Co. “Pub Shop” Initiative

Guidance on Operating Your Food Business During the COVID-19 Crisis

What you need to know about coronavirus and food…

According to the UK Government and Public Health England, it is very unlikely that you can catch coronavirus from food. COVID-19 is a respiratory illness, and it is not known to be transmitted by exposure to food or packaging. Any food handler who is unwell should not be at work. If they have any symptoms of coronavirus, they should follow government advice and stay at home.

Although it is very unlikely that coronavirus is transmitted through food, as a matter of good hygiene practice anyone handling food should wash their hands often with soap and water for at least 20 seconds. This should be done as a matter of routine, before and after handling food, and especially after being in a public place, blowing their nose, coughing or sneezing.

Food business operators should continue to follow the Food Standard Agency’s (FSA) guidance on good hygiene practices in food preparation and their Hazard Analysis and Critical Control Point (HACCP) processes.

Steps all food businesses should be taking;

Employers should stress the importance of more frequent handwashing and maintaining good hygiene practices in food preparation and handling areas. Employees should wash their hands for 20 seconds, especially after being in a public place, blowing their nose, coughing or sneezing

Objects and surfaces that are touched regularly, should be frequently cleaned and disinfected using your standard appropriate cleaning products

If anyone becomes unwell with a new, continuous cough or a high temperature in the business or workplace they should be sent home and advised to follow the stay at home guidance. If you or an employee are experiencing symptoms, visit NHS 111 online or call 111 if there is no internet access

The advice on social distancing measures applies to everyone. You need to minimise opportunities for the virus to spread by maintaining a distance of 2 metres between individuals. The advice applies to both inside the food business and in the external public areas where customers may need to queue. People should be reminded to wash their hands for 20 seconds and more frequently than normal

Effective measures to support the fight against COVID-19 will vary from business to business but could include the following;

TAKEAWAYS AND RESTAURANTS OFFERING A PICK-UP SERVICE

No order should be taken in person on the premises - this should be communicated to customers by appropriate means such as signage

Businesses should therefore only take orders online or by telephone

Customers could have staggered collection times - customers should be discouraged from entering the premises until their order is ready

Customers arriving without having already placed an order should be encouraged to leave the premises to place the order by telephone or online and to return at a designated time for collection

Customers whose orders are ready should enter one at a time to collect orders and make payments

Businesses should discourage crowding outside the premises. Where possible, use queue management systems to maintain the 2 metres separation

SUPERMARKETS AND FOOD STORES

Supermarkets and food stores need to avoid crowding and create adequate spacing between individuals

Monitoring the number of customers within store and limiting access to avoid congestion

Implementing queue management systems to limit crowds gathering at entrances and maintaining the 2 metres distance

Reminding customers to only buy what they need

Public Health England (PHE) supports measures to allow safe privileged access to elderly and essential workers such as NHS and Social Care staff

FOOD PROCESSING PLANTS

Food safety practices in food processing plants should continue to be delivered to the highest hygiene standards including the use of some personal protective equipment and frequent hand washing.

All employers are expected to follow social distancing guidance, including food businesses, as far as is reasonably possible. Where the production environment makes it difficult to do so, employers should consider what measures may be put in place to protect employees.

Details in this article have been obtained from the UK Government (08/04/2020). For more government information and guidance as a food business see the links below;

Target Extends Manufacturing Capabilities to Support the Fight Against Covid-19

British manufacturers Target Catering Equipment are on hand supporting the NHS, healthcare, care and public sectors in this time of national emergency with the manufacture of medical grade stainless steel equipment such as tabling, cabinets, sinks and wash stations.

With over 30 year’s design and manufacture experience, Target has the ability to confidently design, manufacture and upply complete hygienic wash systems including; commercial dishwashing systems, matress washing systems, bed pan washer disinfector systems, BA mask cleaning washer disinfector systems which combine machines specifically approved for the removal of pathogens including those of Coronavirus.

David Pedrette, Managing Director at Target says; “In a bid to help support the UK’s key workers in the fight against Covid-19 we are extending our manufacturing capabilities and prioritising all orders from the NHS, healthcare, care and public sectors, and military, who are all working so hard and doing such a great job of looking after everything.”

“With regards to the operation of our business, the safety of our staff, customers and suppliers is of upmost importance to us and we continue to follow government guidelines. With staff that are able to do so, working remotely from home, and those that are to continue working within the factory, operating in line with strict health and safety regulations and advice provided by the government and NHS.”

From a foodservice and catering perspective, Target continues to operate as usual, designing, manufacturing, supplying and supporting commercial catering equipment to all of those that require it.

Having previously manufactured bespoke equipment for the Royal Navy Queen Elizabeth II aircraft carriers and Astute submarines, Target recognises the improtance of delivering quality equipment that can be relied upon in times of crisis, where focus needs to remain on the mission in hand.

If you have any urgent requirements for the manufacture of bespoke or standard stainless steel equipment contact Target on 01452 410 447 or email enquiries@targetcatering.co.uk