The Top Benefits of Going Sustainable in the Kitchen for Food Industry Businesses

The Oxford dictionary defines sustainability as ‘the ability to be maintained at a certain rate or level’, and the ‘avoidance of the depletion of natural resources in order to maintain an ecological balance’.

When thinking of sustainability, we often think of climate change and the massive steps required by the world to reduce our carbon footprint, but the truth is, sustainability matters in all types of environments, no matter how big or small, and there are a number of things you can do to improve your business’s sustainability, whilst helping in the battle against climate change.

The modern commercial kitchen, for instance, has for many year’s relied upon gas and electric cooking equipment, but how sustainable are they for businesses and how do they compare to the latest cooking technologies including ever-popular induction cooking ranges?

Selecting the right cooking equipment is crucial to any restaurant or other catering business as acquiring the best solution can save on energy usage and reduce overhead costs amongst many other benefits, which ultimately increases profits. So, it’s a big decision to make!

Here, we list some of the top benefits of choosing a commercial induction range for your commercial kitchen and how it can help your business become more sustainable:

Induction - Faster than gas and electric radiant plate hob cooking

One of the foremost advantages of induction cooking technology is its speed. While an electric hotplate takes just under ten minutes to boil 1 litre of water, and gas burner roughly eight minutes, a 3.5kW induction hob can achieve the result in well under three minutes.

Induction technology works by generating heat within the pan base rather than through the transfer of heat from a heating element or flame beneath the pan. Induction technology transfers 90% of energy used directly into the product inside the pan with only 10% waste heat going to atmosphere, compared to a gas which wastes 60% of energy. Making induction hob cooking much more energy efficient, saving time and more importantly energy, which results in a significantly more sustainable cooking process.

Induction - Concentrated heat to reduce energy wastage

It’s well known that commercial kitchens with gas and electric ranges can get incredibly hot especially in summer months. Heat is generated from a source beneath the pot and transferred through the pan into the product, however, in most cases this can result in over half of its heat being lost into the surrounding environment. Whilst this makes for difficult working environments for chefs, it also means 60 percent of the energy it takes to cook something is being wasted, which is an unprecedented amount in the grand scheme of trying to achieve a more sustainable business.

An eco-friendly attribute of the induction range is stopping excess heat from escaping by generating heat directly in the pan and transferring the concentrated energy into the product.

Thus, also keeping kitchens cooler avoiding the need for energy-zapping kitchen ventilation systems and air conditioning heating and cooling systems to keep the room at a comfortable working temperature.

Induction - Glass ceramic cooktops offer long-term durability

The eco-friendly glass ceramic material used in induction cooktops carry many additional benefits.

For instance, glass is a poor heat conductor meaning minimal heat is transferred from the pans across the surface. In fact, you can put your hand around the glass cooking area while the pan is in use and would only be warm to the touch.

The easy cleaning and rapid cool-down of the material also means chefs don’t have to worry about burnt on food, ensuring a durable, easy clean range for long-term commercial use.

Induction - Integrated with smart technology

Another major benefit of the induction cooking ranges is that they can come equipped with many bells and whistles, most of which increase sustainability. Some models, for example, have sensors that can recognise the pan temperature and beep to alert the chef or switch off in a pan boil dry situation.

Overall, induction offers the power, responsiveness and control of gas and the safety with the sustainability of renewably sourced electricity. It can generate high temperatures in a short time, while also being able to heat pots and pans at very low precise temperatures in a short time, while also being able to heat pots and pans at very low precise temperatures, so chefs can cook and boil faster, and simmer with more precision. Its energy saving capabilities make induction cooking significantly more sustainable than its gas and electric alternatives, and help create a healthy, productive and profitable cooking environment.

For more information on induction cooking technology - Click Here

Why Choose a Mobile Cooking Suite Over a Fixed Built-In Suite?

Here at Target Catering Equipment, we specialise in the application of induction cooking technology, providing cost-effective cookline solutions for commercial kitchens that deliver quicker turnaround times of cooking food, safer working environments, reduced carbon footprints and minimal on-going maintenance requirements. We advise businesses on how they can become more sustainable by implementing induction cooking technology and other energy efficient appliances within their commercial kitchen.

Here we will be looking at the differences between mobile and fixed cooking suites and why you might choose a mobile suite over a fixed built-in suite.

Originally, range suites were the mainstay and source of chef’s-pride in European kitchens, however they have since been making their way into mainstream commercial kitchens around the world, partially driven by the popularity of open or display kitchen designs.

Range suites are cooking centres that are traditionally arranged as a closed island of cooking splendour. Many European and classically trained chefs gravitate to these suites, when equipment cost is no object and space is available as they can easily accommodate several chefs and assistants, and their arrangement allows for easier communication within the kitchen.

In more recent years, with the size of many kitchens getting smaller and the development of modern commercial induction technology, cooking suites are growing rapidly in popularity, becoming more varied and accessible in style and design, which means they are suitable for commercial kitchens of all shapes and sizes.

So, what are the main differences between fixed and mobile cooking suites?

Traditional Gas Fired Fixed Built-In Suite

Traditional gas fired island suites are manufactured out of heavy duty 3mm thick stainless steel, with built-in appliances such as solid top plates, open burners, griddles, braising pans to name just a few. These built-in appliances are heavy and require a framework that can withstand the heavy-handed nature and heat that comes with working with gas appliances and large, heavy cookware and are therefore typically fixed in one place, non-manoeuvrable with gas, electrical, water and waste services running underground. This requirement of lots of heavy thick material increases the cost of the suite and increases its impact on the environment.

Modern induction cooking technology and electric appliances are more lightweight and do not require gas pipework to fuel the equipment. Being lightweight means, you do not need the support structure as required with gas appliances which in turn means less material is required in framework, reducing the impact on the environment, reducing material costs in manufacture and allowing units to be fitted on castors, making them mobile.

So, why would you choose a mobile suite over a fixed suite…?

Target Mobile Induction Suite

Mobile induction suites can be easily moved to allow for easy cleaning especially when situated up against a wall. Favoured by Environmental Health Officers as they allow for deep cleaning with the kitchen, making it significantly easier to maintain a 5* hygiene rating. Carrying out regular deep cleans is essential for eliminating potential health hazards, formed by food spills and residue that gets into hard to reach places. If kept unchecked, unwanted bacteria and vermin can thrive within these in-accessible dirt traps.

The ability to pull out these units allows for easy access to built-in appliances, necessary for when faults or damages occur or when PPM (planned preventative maintenance) and servicing checks are required. It also provides easy access to plumbing and electrical services, making jobs easier for engineers and kitchens staff.

Should your mobile cooking suite experience a malfunction, its ability to be moved with ease allows for a simple removal from site for repair if required, without causing disruption to other kitchen appliances. This also allows for temporary equipment to be put in as a stand in until the suite is operations again allowing your business to carry on as usual.

When fixed cooking suites are installed, they are often delivered part manufactured and finished on site. This often means units once installed will be too large to remove from a property and as such become a fixed asset within said property. For those that do not own properties freehold, or those that plan to relocate or expand in the future a fixed suite can be an expensive outlay cost and restrict your future business plans.

Kitchens with fixed suites can also be restricted as once an arrangement has been selected it would have a big impact on the kitchen’s operation and cost implications if any changes to the configuration were needed, therefore businesses can be tied to a suit which doesn’t meet their current preferred menu requirements.

Mobile suites are typically manufactured off site and delivered as a whole unit, reducing interference and down time to operating kitchens. Units are simply wheeled into position, plugged in to pre-installed services and ready to go within minutes.

The manoeuvrability of mobile cooking ranges means that they don’t become a fixed asset part of the building and can be removed and relocated as and when necessary. This offers greater flexibility, especially for future kitchen developments, when it may be necessary to upgrade, reposition or even re-sell a suite to allow for sequential and efficient cooking/preparation processes. This also applies to menu changes, which can be catered to by moving the appliances around to suit new cooking methods and requirements.

With modern induction technology, air flow around the electrical components is critical for ensuring optimum operating conditions thus ensuring premium performance of the appliance. With fixed suites you restrict the circulation of airflow throughout the unit which has negative effects on the performance of the components. With raised mobile units air can be pulled over and pushed out over components keeping them cool and operating efficiently.

Mobile suites are the way forward if you are forward planning and want to keep flexibility within your commercial kitchen, take a look at our range options HERE.

How to Choose the Right Cookware for Your Induction Hob

Induction cooking technology is undoubtedly a great investment for any commercial kitchen, providing a range of safety features, improved cooking processes, efficiency and cost benefits - which are just a few of its valuable plus points. However, if you find your pans are not heating up properly and your induction equipment is lacking in power, it’s likely to be down to the material of the pan that you’re using!

Induction powered cooking hobs generate heat through a combination of components, which includes; a generator, a coil, a high-frequency electromagnetic field and magnetic cookware. As the pot or pan is a key component of induction cooking technology, the type of pan used can have a direct effect on the performance of the technology itself.

It’s important that a pan has very good electrical resistance if it’s to function on induction. If the pan is made, for example, from aluminium, copper, silver or gold, a current that’s too high can flow in the base of the pan, meaning no heat will develop. Additionally, many assume that all magnetic pans work on induction; but this is not always the case.

When considering the performance of pans for cooking purposes, the base of the pan does not play a major role. The overall material and thickness of the pan is what affects the distribution and consistency of heat.

If you’re often confused with which pans are compatible and work best with induction hobs, below explains the different types of induction-friendly cookware available.

COMPOSITE BASE

The ‘composite’ describes the base of the pan, which is made from several layers. This usually consists of, a thick middle layer of aluminium or copper, and a thin steel alloy base. The body of composite base pans may be either aluminium, copper or a high-grade steel alloy.

Composite base pans are great for heat distribution; however, aluminium and copper can deteriorate through the use of cleaning agents.

MULTI-LAYER

Multi-layer pans are made entirely from either one layer and/or several layers of material, without changing the actual base. The interior layer is typically made of high-grade steel, the core made of aluminium and the external layer made of high-grade steel.

Multi-layer pans react rapidly to changes of power in the pan, giving excellent temperature control. If the pan walls are the same thickness as the base, the heat-up speed is very fast especially if the pot has a lot of food contents in it. However, if the pot only has a small amount of food inside, a lot of heat is lost to the walls of the pan. If the pan has a thin base, little heat transfer can take place, and there will be uneven heat distribution within the pan. Typically, multi-layer pans have good non-stick qualities and are very easy to keep clean.

CAST IRON

These pans are made from 100% cast iron and have magnetic qualities suitable for cooking with induction.

Cast-iron pans have good heat storage properties. However, they are heavy and take longer to build up heat, due to the material thickness. Typically, cast-iron pans have rough surfaces and therefore, can be difficult to keep clean.

PRESSED BASE

These pans are made from cast aluminium with an induction compatible layer. The aluminium casting is then pressed or melted into this. In most cases, pressed pans are compatible for use with induction; but not all.

When considering the materials of the pan, if an aluminium ring is used on the outer edge of the pan base, this can act like a magnetic short circuit. This means that if the coil is smaller than the pressed pan base the pan can still function. If, however, the coil is larger than the pan, the aluminium ring attempts to heat up, which causes poor performance within the pan.

Pressed pans are typically light weight and provide good heat distribution.

Here at Target Catering Equipment, we recommend Demeyere commercial grade cookware suitable for use with our commercial induction hobs. We’re also on hand to provide you with advice on the best accessories for your hob, in addition to cookware maintenance.

To find out more contact us here.

Lincat Expands 'No Frills' Phoenix Range With New Single-Phase Induction Oven Range

Lincat has launched a single-phase induction oven range as part of its ‘no frills’ Phoenix range of medium-duty prime commercial catering equipment. The PHER01/SPH induction oven range has been introduced in response to demand for the model from establishments with single-phase power.

At 800mm deep and 900mm wide, the powerful range is energy efficient and robustly constructed. The easy-to-clean induction hob top is constructed from 6mm thick high impact resistant glass. It features six 1.85kW induction zones, which can be boosted to 3kW when intense heat to conserve energy and ensures that heat is not lost into the kitchen.

Below, a powerful, twin fan-assisted 6kW oven provides fast heat-up times and is able to accommodate six 1/1 gastronorms, enabling different foods to be cooked simultaneously. Heavy-duty castors, to facilitate cleaning, are provided as standard.

In addition to the induction oven range, Lincat’s new Phoenix electric salamander is now available to order, following its launch at the Restaurant Show last month. The PHEAS01 is equipped with fast heat up ‘Hi-Light’ elements, which are ready to cook in just eight seconds. It has three heat zones, enabling the operator to only switch on the area required, to conserve energy.

Helen Applewhite, Marketing Manager of Lincat Ltd, said:

“Operators would have traditionally paid more for energy efficient equipment such as this, but our no frills Phoenix range provides cutting edge technology at an affordable price. This is why we have experienced positive pre-sale demand for Phoenix products.”

How Do Target Induction Hobs Work?

Here at Target Catering Equipment, we believe that induction hobs are not only more environmentally friendly and safer than other hob types, but they’re also more efficient and perfectly suited to many different cooking styles. Additionally, induction hobs use much less energy and can be powered by renewable energy sources.

The process behind their function is slightly different to other traditional types such as gas and radiant plate hobs and we think that learning how induction hobs work will not only help you understand the technology, but also help you to get the most out of your appliance, enabling you to produce great quality food time after time.

Unlike other hob types, our induction hobs do not radiate heat from the source - i.e. from a flame or heated plate. The heat is actually generated through the pan itself, hence why the pan heats up, but the hob surface remains cool. Underneath the glass surface is an electrical circuit which, when completed, allows the user to cook food.

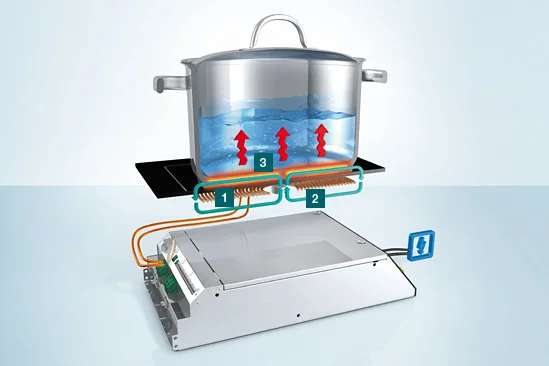

The circuit begins with a generator, which when the hob is switched on, sends an electrical current through a copper coil - this creates a high-frequency electromagnetic field. For the circuit to be completed, an induction-friendly magnetic pan must be recognised by the pan sensor located beneath the hob glass. Heat convection then takes place within the pan, allowing cooking processes to begin.

1. Copper Coil

2. Elecromagnetic Field

3. Heat Generated

During cooking, the glass hob remains cool since the heat is emitted from the pan itself rather than the surface - and as soon as the pan is removed, the circuit is terminated, thus turning the hob off. This is a much safer cooking method to use within busy commercial kitchens as burns are much less likely to occur and fire risks can be greatly reduced; not to mention the overhead cost reduction thanks to the energy savings that induction hobs generate.

Since the cool surfaces help in maintaining a lower room temperature, induction hobs are also great for industrial kitchen environments. Additionally, thanks to their flat surfaces and specific requirements for use (i.e. magnetic pans), these hobs can be safely used as extra worksurfaces when not in use.

At Target Catering Equipment, we offer a range of induction hobs and commercial induction ranges. To take a look at our products in more detail, please see here.

Why Choose Induction Hobs Over Gas Hobs?

Choosing the right hob for you can often be a challenge - especially considering the wide range of options available. Induction hobs are undoubtedly on the upper end of the price spectrum and considered an investment for many businesses, however they most certainly offer a great return given their functional and environmental benefits.

Here at Target Catering Equipment, we’ve considered the advantages and disadvantages of gas hobs and kept these in mind when developing our bespoke commercial induction suites by incorporating the very latest commercial induction hob technologies.

Using gas hobs in any commercial kitchen - large or small, can make for an extremely heated environment, creating tough working conditions for chefs. We believe in providing only the best catering equipment to make cooking an enjoyable yet efficient experience.

Induction hobs only consume energy when an induction-friendly pan is placed on the cooktop. This action completes the electrical circuit. The hob and induction element itself always remain cool and automatically switches off when the pan is removed; thus, heat is only emitted from the pan rather than the hob. This creates a whole range of safety benefits, whilst also keeping kitchens cooler. Additionally, compared to the 40% energy efficiency of gas hobs, induction hobs are 90% energy efficient completing cooking tasks much quicker - so the return on your investment is much greater. The maintenance requirements are also comparatively low, making the day to day running of the kitchen a much less stressful experience.

In addition to cooler cooking environments, induction hobs are much safer for industrial use since there’s a lower risk of fire and staff injuries - allowing the working day to run more smoothly. This highly effective cooking method allows for consistent production of quality food at a more efficient rate, ultimately improving customer turnover and profit.

Induction hobs are an extremely smart range of hobs, making cooking easy and safe without having to compensate on the quality of food or service. These hobs offer highly accurate temperature control, whilst also reducing the risk of food spoilage, and the chances of staff misuse is greatly reduced thanks to its simplistic and safe design. Induction hobs are also incredibly flexible in use compared with gas hobs, since they support a whole range of cooking styles and the cool, flat surface can be used as extra space for preparation when not in use.

Above all else, induction hobs are environmentally friendly. Unlike gas hobs, there is minimal risk of wasted energy being emitted into the atmosphere and can be powered by renewable energy sources. These hobs can greatly reduce your company’s impact on the environment, whilst improving overall sustainability for the business.

Induction hobs are cost effective, multi-functional, flexible and great for the environment - allowing for efficient, guilt-free cooking all day long.

To view our vast range of induction hobs, Click Here.

Target Engaged to Help Deliver UK's First Chinese Culinary Arts Qualification

With the UK's Chinese restaurant industry suffering from a severe shortage of skilled staff, the launch of an industry recognised Chinese Culinary Arts (LuBan) Diploma qualification, specialising in Chinese cuisine, culture and culinary arts couldn't have come at a better time.

Traditionally, skills and techniques required in the Chinese foodservice industry have been passed down from generation to generation with businesses also being passed down through family members. However, with younger generations now favouring alternative careers, restaurant owners are having to look elsewhere for skilled staff.

Combine this need with the UK government's £750 million collaboration agreement to support China's One Belt One Road initiative and the result is the UK's first industry recognised Chinese Culinary Arts (LuBan) Diploma qualification.

Developed by PAM Education and Tianjin School of Commerce the Chinese Culinary Arts (LuBan) Level 3 Diploma has been created and approved by British Education qualification awarding body Qualifi.

Following multiple visits to various education providers it became apparent that traditional British training kitchens were not equipped towards Asian cuisine and were therefore unable to deliver the requirements of the course. With this in mind, PAM Education and Tianjin School of Commerce approached Target Catering Equipment as specialist commercial kitchen design consultants to prepare a training kitchen layout that would meet their exact needs and requirements.

Target, having previously worked with many Asian restaurants in the UK and recently completing a complete kitchen design for a staff canteen in a large leading electrical component factory based in China displayed the knowledge and services that were required to move the project forward to its next stage of implementation.

"Working within the foodservice industry for over 30 years, we regularly hear about the lack of skills and training available, specifically in the Asian sector. It is great that this is finally being recognised and something is being done about it as it plays a huge part within the entire foodservice industry." Says David Pedrette Managing Director of Target Catering Equipment.

Crawley College was selected as the site dedicated to the course, leading the way, offering the UK's first dedicated, industry recognised qualification in Chinese Culinary Arts. The new training kitchen was designed and featured the very latest induction wok ranges as requested by Tianjin School of Commerce, a decision highly supported by designers Target, as the technology is fast being recognised as the future of Chinese and other Asian commercial kitchens.

Designs approved, the dedicated kitchen was installed at the college and following an inspection by Tianjin School of Commerce Master Chefs, the facility was given the go-ahead to start offering the much-needed vocational skills training to a unique sector of the international food scene centred around the UK's Asian restaurant sector.

With the first course due to start in September 2018 at Crawley College, chefs and individuals either looking to begin a career or expand their knowledge and skill set within the Chinese foodservice industry are invited to enrol and open their career prospects across the world.

For more information visit: www.crawley.ac.uk/study-courses/course-list/81CCD3-Chinese-Culinary-Arts-Lu-Ban-Diploma-Level-3

English Vineyard Wins Thousands by Switching to Induction

English wine producers, Three Choirs Vineyards, wins over three thousand nine hundred pounds in grant funding by switching to Target commercial induction equipment. Awarded by the Carbon Trust Green Business Fund, for the upgrade of out dated inefficient gas commercial kitchen equipment at their Gloucestershire site to induction, the energy efficient alternative.

With the existing kitchen ventilation system struggling to cope with the waste heat being produced by the LPG gas cookline, combined with the rise in utilities costs, the decision was made to convert the current kitchen equipment to the latest energy saving induction technology.

Assisted by Target Catering Equipment accredited Carbon Trust suppliers, who completed the detailed energy saving assessment, the Three Choirs Vineyards applied for Green Business Funding for fifteen percent of the project cost up to the value of £5,000.

With potential energy saving figures predicted, the Carbon Trust granted the vineyard £3,942.84 towards the new equipment, which included, a bespoke Target commercial induction range complete with induction plancha, induction 4 zone solid top, induction 2 zone hob, twin tank FriFri fryer, Turbofan® convection oven and fast action rise and fall salamander grill.

The Three Choirs Vineyard, Gloucestershire now operates an energy efficient kitchen delivering top quality food with award winning wines.

For more information on the Carbon Trust – Green Business Funding opportunities to reduce energy consumption and costs when upgrading commercial kitchens contact Target Catering Equipment CALL NOW 01452 410 447

Carbon Trust Green Business Funding is limited an available on a first come first serve basis, so don’t delay in getting your application in. It costs nothing, and you could gain up to £5,000 towards the cost of new equipment when replacing in-efficient equipment.

Guide to Commercial Plancha Cooking

Having recently introduced the commerical induction plancha as a bespoke induction range configuration option, Target brings to you a guide on plancha cooking, explaining the differences between electric griddles, electric planchas and induction planchas.

THE DEFINITION OF 'PLANCHA COOKING' IS, TO COOK FOOD DIRECTLY ON A HOT OILED PLATE.

Induction Plancha

Electric Griddle

Electric Plancha

All three pieces of equipment listed above are typically hot metal plates used to cook food directly on. The type of metal plate will vary from each manufacturer of product, with each having different conductivity characteristics.

Heating Technology

How the hot metal plate is heated will affect the characteristics of the plate surface, resulting in different outcomes when cooking.

Electric Griddle

The electric griddle most commonly uses rod elements for heating the griddle plate surface. This type of electrical element is the slowest to react to change in temperature setting and can deliver inconsistent surface temperatures, with hotspots where the element is directly below or in contact with the metal surface.

Electric Plancha

The electric plancha or French plancha, as it is sometimes called, typically uses a filament element for heating the plancha plate surface. Filament elements tend not to cover the entire surface of the plate and rely on heat dispersion to distribute heat across the surface. This results in graduated temperatures from hot to cool from the middle to the edge of the plancha cooking surface, a characteristic similar to the gas solid top.

Heat up times of the electric plancha from 20°C to 230°C takes approx. 20-30minutes. However, this temperature would not be consistent across the entire plancha plate.

Induction Plancha

The induction plancha uses the same type of coil elements as used with induction hobs. The induction coil element covers the entire plancha plate surface, optimizing operational efficiency by providing uniform heat distribution from corner to corner.

The speed of temperature control depends on the composition of metal used in the plate surface, however, is by far the fastest out of the three equipment types. The instant energy transmission from induction coil to plancha plate surface allows for fast start up times, for example;

The commercial induction plancha used in Target induction ranges heats up from 20°C to 230°C in just 4½ minutes on the single zone 3.5kW induction plancha and just 3 minutes on the single zone 5kW induction plancha.

Temperature Monitoring & Recovery

For consistent cooking precise temperature monitoring is required.

Electric Griddle

Electric griddle plates are typically manufactured from mild steel which is a cheaper material when compared to chrome plated steel or composite stainless steel. Mild steel has relatively poor conductivity properties and therefore is affected when cold produce contacts the surface, fluctuating cooking temperatures.

The rod elements used for heating the plate are thermostatically controlled and regulate the temperature of the cooking surface. Temperature regulation is electro mechanical, with a poor degree of accuracy and reactiveness, which results in users having to move product around the griddle as temperatures vary across the grill plate.

Electric Plancha

Quality electric plancha plates are manufactured from thick steel, this maximises thermal retention and minimises fluctuations in surface temperatures when cold produce contact the surface. However, the use of thick steel reduces the conductivity which means heat up and temperature change times are prolonged.

Surface temperatures are monitored using a temperature probe, situated between the plate and the element. However, the probe is usually unable to read the temperature at the centre of the element where it is hottest and can therefore be unreliable when it comes to temperature control.

The heat retention characteristics of the plancha plate minimises fluctuations in the surface temperature, therefore, there would need to be a dramatic drop for the probe to detect a change and bring the plate back to the temperature it was set at.

Induction Plancha

The commercial induction plancha plate is a composite of different metals. The induction plancha plates that are used in Target ranges are made up of steel and aluminium. Joining the magnetic characteristics required for use of induction technology with the heat conductivity characteristics found with aluminium. Combined, results in fast heat up times and rapid temperature control.

Having a thinner metal plate means the cooktop is more susceptible to plate temperature change, which occurs when cold food is placed on the plate, however this can be overcome with the use of RTCSmp® (Real-Time Temperature Control System Multi Point) providing precise temperature monitoring across the entire cooking surface.

RTCSmp® uses multiple sensors embedded across the plancha plate surface to detect a deviation in temperature as small as one-half degree, the temperature is then automatically adjusted in that specific area, providing a highly consistent, responsive, surface to cook on.

Not only does the RTCSmp® regulate the temperature of the cook zone, the technology also monitors continuously in real-time, the energy supply and the state of the components such as the induction coil. Should a malfunction occur, the integrated fault diagnostic system reports the malfunction instantly to the user.

Correct Operation

Although seemingly similar to a solid top appliance, all three pieces of equipment featured in this guide are intended to be used for cooking produce directly on, without the use of a pan.

By using a pan on any of these pieces of equipment you run the risk of creating hot spots on the plate as heat can be conducted back into the surface which can cause plates to warp and can also create malfunctions in the technology systems beneath.

For those looking for an energy efficient alternative to the gas solid top, where multiple pans are to be used for cooking, a graduated slide top induction hob with single control is the best like for like option currently available on the market from Target Catering Equipment.

Overview

The electric griddle offers an appliance with a surface that delivers inconsistent temperatures across the plate with long heat up times and provides limited temperature controllability.

The electric plancha surface delivers gradient temperatures from the centre to the edges of the plate, suitable for varying product finishes. The plate characteristics result in longer heat up and temperature change reaction times.

The commerical induction plancha surface delivers consistent temperatures across the entire plate surface, suitable for cooking quantities of produce to the same finish. Heat up times are minimal, and controllability is highly reactive.

Tewkesbury Garden Centre Goes Green!

Thumbs up from Head Chef at Tewkesbury Garden Centre as owner Rachel Gallagher receives almost four thousand pounds Green Business Funding from the Carbon Trust to improve the restaurant's kitchen equipment making it more energy efficient and user friendly as the business continues to grow.

Famed for using local food produce and suppliers the garden centre restaurant goes from strength to strength, now working with local manufacturer and Carbon Trust accredited supplier Target Catering Equipment to provide the new kitchen equipment.

With the help from Target Catering Equipment Rachel was able to submit an application and prove to the Carbon Trust that switching from the existing electric hotplate hobs and basic electric oven to a Target six zone induction range with Blue Seal Turbofan ® convection oven would be more energy efficient and sustainable for the business. This in turn lead to the Green Business Funding capital contribution being awarded.

The small kitchen can now keep up with customers' demands, and with a team of dedicated staff, can continue to produce quality local farmhouse food.

For more information on the Carbon Trust - Green Business Funding opportunities to reduce energy consumption and costs when upgrading commercial kitchens contact Target Catering Equipment CALL NOW 01452 410 447.

Carbon Trust Green Business Funding is limited and available on a first come first serve basis, so don't delay in getting your application in. It costs nothing and you could gain up to £10,000 towards the cost of new equipment when replacing in-efficient equipment.

The Advantages Of Using Induction Hobs

The Advantages Of Induction Hobs

Gas hobs have long been the first choice for professional kitchens all over the world. However in recent years we've seen an increasing number of foodservice establishments across the UK and Europe adopting the induction style of cooking. This method of hob based cooking is not only limited to homeowners, but professional kitchens are choosing to incorporate induction hobs into their new kitchen designs, here's a quick rundown of just why this type of cooking is becoming increasingly popular.

Speed - The process of induction means that the pan heats up much more quickly than with gas or electric radiant based cooking. Induction hobs work by using electromagnetic currents in the cooktop to trigger electromagnetic activity in the pan, so the pan effectively heats itself up without the middleman ie. flames. This means less time waiting for things to heat up so therefore the food can be cooked quicker. In a restaurant environment this means much quicker service and happy customers.

Energy efficiency - With the pan heating itself up more of that heat can go directly to the food, gas and electric hobs give off radiant heat which heats everything around them. In a professional kitchen environment this means a lot less radiant heat is emitted during cooking; a cooler kitchen means happier, more efficient chefs! Induction hobs are a much more energy efficient way to cook due to the reduced energy consumption that also comes with quicker cooking.

Safety - The hob area can be one of the most dangerous places in the kitchen whether a domestic one or a professional one. Induction hobs are much safer than gas or electric radiant hobs because it is the pan, and the product within that gets hot rather than the stove. No flames means no accidental fires, and no gas means no gas leaks.

Control - Professional chefs have always preferred gas stoves over electric as gas is much more responsive when you turn it up or down. Induction hobs are just as, if not more responsive as gas hobs when the temperature is increased or decreased. In fact, induction cooktops allow better control with smaller temperature increments and better performance at low temperatures so it's much easier to keep things warm without burning or overcooking them.

Cleaning - The fact that an induction hob doesn't get hot (other than from the heat of the pan) means that food residue doesn't burn onto the cooktop. A spillage just calls for a quick wipe rather than an intense scrub and can be done whilst in use. The surface of induction hobs are completely flat too so it's incredibly easy to wipe over compared to gas or electric radiant hobs with bits that detach and protrude!

Target Leads the Way with Innovative Catering Equipment

Target Catering Equipment announced as winners of the Gloucestershire Business Show 2016 award for ‘Innovation in Business’. As trail-blazers within the foodservice industry, Target Catering Equipment have worked tirelessly over the past 8 years to change business owners and chefs’ perceptions of commercial kitchens across the UK, through the development of innovative catering equipment.

Target Catering Equipment wins Business Show Innovation Award for changing perceptions of commercial kitchens.

Target Catering Equipment announced as winners of the Gloucestershire Business Show 2016 award for ‘Innovation in Business’. As trail-blazers within the foodservice industry, Target Catering Equipment have worked tirelessly over the past 8 years to change business owners and chefs’ perceptions of commercial kitchens across the UK, through the development of innovative catering equipment.

“If you can’t stand the heat keep out of the kitchen” used to be the saying but with Target Catering Equipment’s innovative approach to developing technology, this is no longer the mantra of chefs.

“Need - is the mother of invention and innovation” Recognising that cooler more efficient kitchens were needed by business owners, in order to minimise overhead costs, improve working conditions and attract the best chefs to work in their commercial kitchens, Target began research and development into commercial induction cooking equipment which had previously been written off by larger manufacturers, preferring gas for speed, controllability and cheap manufacturing costs.

With the Government also striving to reach Kyoto 2020 energy reduction and reduced carbon footprint targets, commercial kitchens have been regarded as high energy consumers with massive energy waste and increased carbon emissions that are now under increased scrutiny by the Carbon Trust who have continued to implement new initiatives to reduce energy consumption, and waste and increase renewable energy supplies.

Through Target’s continued development and ability to custom manufacture equipment to suit individual requirements, induction cooking technology is now considered by many within the industry as one of the best forms of cooking technology. Businesses making the decision to invest in the latest innovative catering equipment are seeing the instant and long term benefits of becoming a more sustainable and efficient business.

Gloucestershire is becoming a hub for green energy innovation design and development with many other specialist businesses located to the area. Target Catering Equipment continues to develop new ideas and technologies within the foodservice industry combined with other leading European manufacturers of equipment, and anyone who is interested in improving their business by investing in the latest innovative commercial kitchen equipment should contact Target.